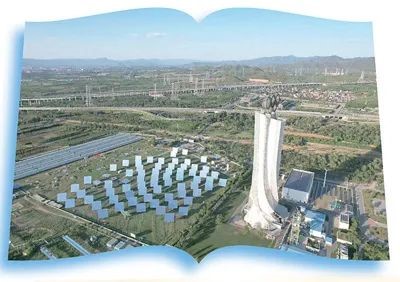

The world's first supercritical carbon dioxide CSP experimental power station. Photo provided by the Institute of Electrical Engineering, Chinese Academy of Sciences.

At the foot of Badaling Great Wall in Yanqing, Beijing, a white tower over a hundred meters high stands majestically, with a tens-of-thousands-of-square-meters heliostat field gleaming under the clear sky. This is the world's first supercritical carbon dioxide CSP experimental power station.

By converting solar energy into electricity through the transformation of "light—heat—work," CSP has advantages such as being green and low-carbon, and having relatively stable power output. It has a broad prospect and is also one of the directions for global new energy exploration. However, due to limitations in power generation efficiency, compared with photovoltaic power generation, this technology does not have a cost advantage, which affects its promotion. There is a need to develop a new generation of technologies that are low-cost, high-efficiency, and highly flexible.

Starting in 2019, the Institute of Electrical Engineering, Chinese Academy of Sciences, took the lead in a joint effort with 18 units to develop a supercritical carbon dioxide CSP unit.

"No one has done this work before. We are exploring in a 'no man's land' with every step," said Wang Zhifeng, the project leader and a researcher at the Institute of Electrical Engineering, Chinese Academy of Sciences. The task involves multiple aspects, including basic theoretical research, technical equipment development, and system integration, with each aspect being a tough challenge.

Take the heat absorption medium as an example. Since the focusing temperature exceeds 700 degrees Celsius, commonly used binary nitrate molten salts are not suitable. After continuous research, the researchers finally developed high-temperature-resistant ceramic particle materials and heat absorbers. To improve fluidity and thermal stability, the particle size distribution was optimized, and an efficient particle transportation device was designed.

"The greater challenge is how to reasonably determine the parameters of each piece of equipment," Wang Zhifeng explained. Some process parameters, if set too high, cannot be achieved by the equipment, while if set too low, the equipment's capabilities are not fully utilized, and the project's predetermined performance indicators cannot be met. To find a balanced value for overall performance, continuous discussions, coordination, and debugging have become routine for the team.

The research team also explored innovative models. "In the past, research projects were mostly centered around research institutions. We explored a model with a design institute as the main body to link the innovation chain from basic research to system integration," Wang Zhifeng said. Practice has proven that this model is very effective in tackling major scientific research projects.

In August of last year, after five years of technical research and engineering construction, the joint team successfully developed the world's first supercritical carbon dioxide CSP unit, using carbon dioxide as the working fluid and ceramic particles as the medium.

In recent years, China's solar thermal power generation has developed rapidly, with more than 30 projects currently under construction. Wang Zhifeng said that the supercritical carbon dioxide CSP technology is expected to increase the overall efficiency of solar thermal power generation systems to over 50%, thereby significantly reducing power generation costs and facilitating large-scale commercial application.

It is reported that during the development of the project, the development of high-temperature materials, precision manufacturing, and intelligent control fields was also driven, and the competitiveness of China's related industrial chains has been enhanced.

Secret to Innovation

For engineering technology, the transition from concept to product involves multiple links. Any weak link can potentially affect the implementation of the technology. It is essential to pool the wisdom of research institutions, production enterprises, and others to work collaboratively and truly serve the industry