On December 29, 2019, China Power Engineering Hami 50MW Tower CSP Project was successfully connected to the grid for the first time. The long shaft molten salt pump used in this project is provided by three manufacturers, two imported brands and one domestic brand. The domestic brand long shaft molten salt pump is provided by Jinan Warwic Pump Co., Ltd.

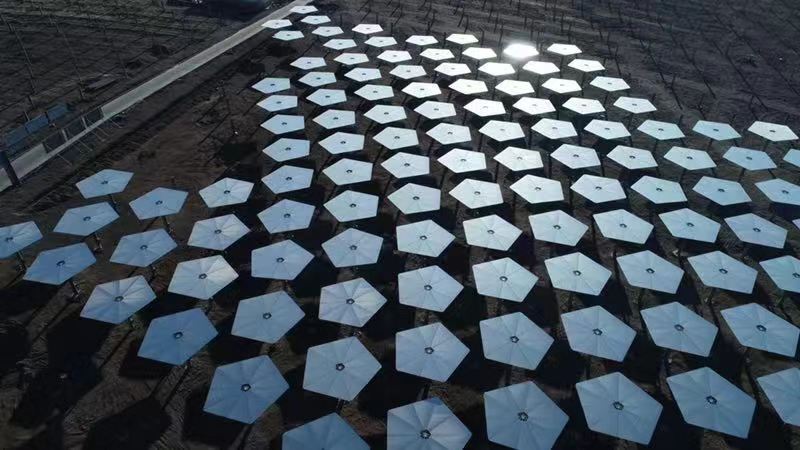

INTRODUCTION OF 50MW CSP PROJECT

The same platform uses molten salt pumps from three manufacturers, and the success of Warwick Pumps' long shaft molten salt pumps is verified through comparative applications. This indicates that the localization rate of key equipment for solar thermal power generation in China has further increased, and the long shaft molten salt pump has completely broken the monopoly of foreign products.

China Power Engineering Hami Tower 50MW CSP project is one of the first batch of CSP demonstration projects in the country. The project has a total investment of 1.6 billion yuan and covers an area of 440 hectares. The planned capacity of the project is 2 × 50MW. After the project is completed and put into operation, it can supply 198.3 million kWh of clean power and save 61,900 tons of standard coal each year. It has a positive demonstration effect on promoting the development and progress of China's CSP industry chain. .

LONG SHAFT MOLTEN SALT PUMP DEVELOPMENT HISTORY

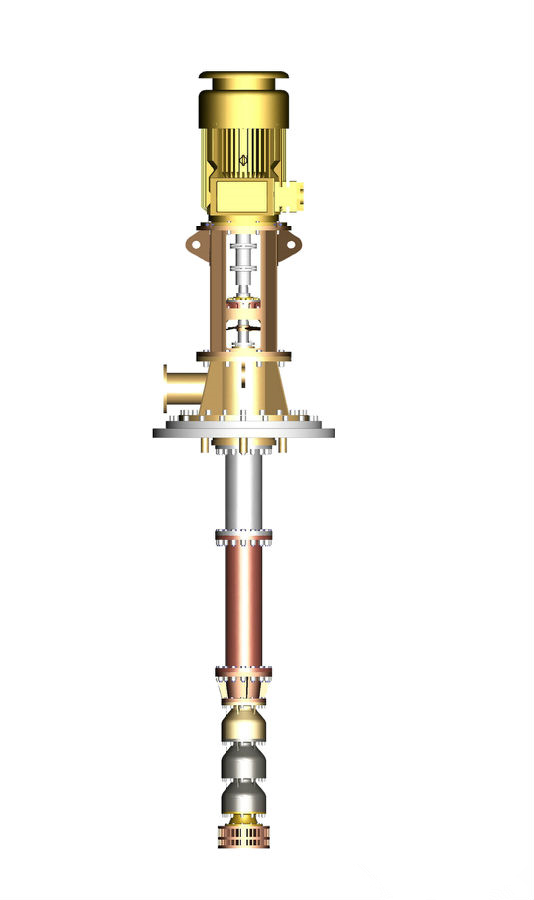

The molten salt pump used in the tower type 50MW CSP project has a submerged depth of 17.35 meters, which is the longest molten salt pump in China. The pump uses the VS1 structure and is designed, manufactured and manufactured in accordance with API610 standard.

1. On August 29, 2018, the structural design, material selection, finite element simulation, thermal temperature field analysis, and hydraulic model design of the long shaft molten salt pump were completed, and production was subsequently arranged.

2. On May 10, 2019, the long shaft molten salt pump was tested in the factory, and the whole machine was tested and installed. After disassembly and inspection, it was packed in a box and waited for shipment.

3. On October 15, 2019, the long shaft molten salt pump was assembled at the Hami project site, waiting to be hoisted in place.

4. On October 23, 2019, the long shaft molten salt pump was hoisted into place and smoothly installed on the 18-meter-high molten salt tank platform.

5. On December 18, 2019, the thermal load of the long shaft molten salt pump was successfully commissioned for one time. The performance parameters of the molten salt pump fully meet the design requirements and run smoothly. Some indicators are better than foreign brands, which indicates that the first domestically produced long shaft molten salt pump has been successfully developed!

SIGNIFICANCE OF SUCCESSFUL DEVELOPMENT OF LONG SHAFT MOLTEN SALT PUMP

Long shaft molten salt pump was successfully applied in Hami tower type 50MW CSP project. Testing with high temperature molten salt verified that Warwick Pump has the ability to develop, design, produce and manufacture long shaft molten salt pumps for CSP projects. At the same time, it proves that domestic molten salt pump has the following advantages:

1. Our molten salt pumps were delivered earliest and have the advantage of short delivery times.

2. The price of molten salt pump is about 40% lower than that of imported brands, which has an absolute cost advantage.

3. Provide localization services during project design, installation, commissioning and training.

ABOUT JINAN WARWICK PUMP CO., LTD.

Jinan Warwick Pump Co., Ltd. is a professional manufacturer of molten salt pumps. The molten salt pumps produced by the company are widely used in chemical and heat treatment industries. Based on years of development and design of molten salt pumps, Warwick Pump Industry has boldly innovated and explored. We and April 2017 successfully developed a long shaft molten salt pump product with completely independent intellectual property rights, and its comprehensive performance indicators have reached those of similar international products. The advanced level has filled the domestic gap.