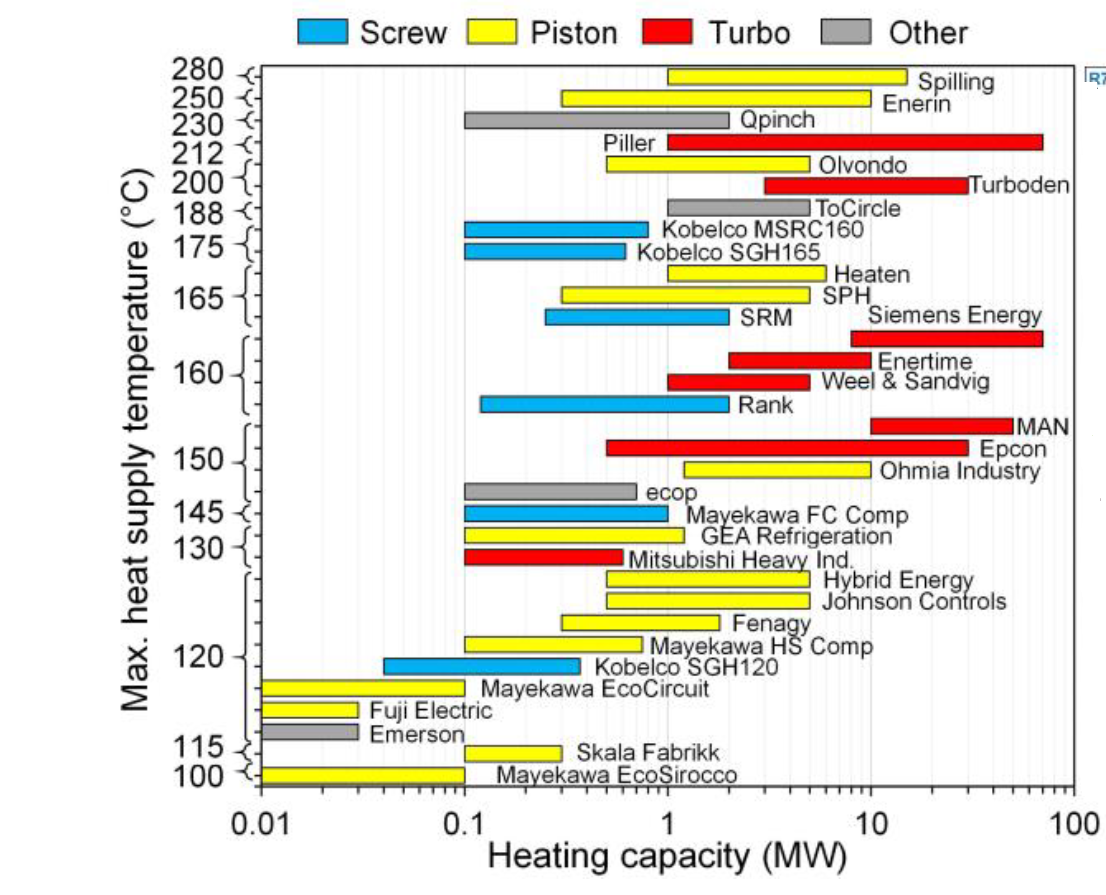

The market for high-temperature heat pumps for industrial applications is developing very dynamically. The number of manufacturers has doubled in the last six years. This is confirmed by Dr Cordin Arpagaus, who has been closely following the industry since 2018. As a Senior Research Engineer at the IES Institute for Energy Systems at the OST Eastern Switzerland University of Applied Sciences, he regularly conducts industry surveys among heat pump manufacturers and has written a book on “High-Temperature Heat Pumps” [1]. In May 2023 he published a conference paper on “Integration of High-Temperature Heat Pumps in Swiss Industrial Processes” for the IEA Heat Pump Conference in the USA, from which the above overview is taken. For a conference on heat pumps and refrigeration technology in Switzerland in June 2024, he prepared a paper titled “Overview of Industrial and Large Heat Pumps” in German. We talked to him about the market and technology development in this segment.

Source: Arpagaus et al. (2023) [2]

Dr Cordin Arpagaus, Senior Research Engineer at the Institute for Energy Systems IES at the OST Eastern Switzerland University of Applied Sciences, has been conducting regular surveys among suppliers of industrial heat pumps since 2018. Photo: OST

You have been monitoring the market for industrial heat pumps and high-temperature heat pumps since 2018. How has the market changed?

Arpagaus: Industrial heat pumps are developing very dynamically. They are versatile and can be used to provide process heat. The new legislation on decarbonization and electrification in industry has boosted demand for large heat pumps. The number of manufacturers of large heat pumps has doubled in the last five to six years.

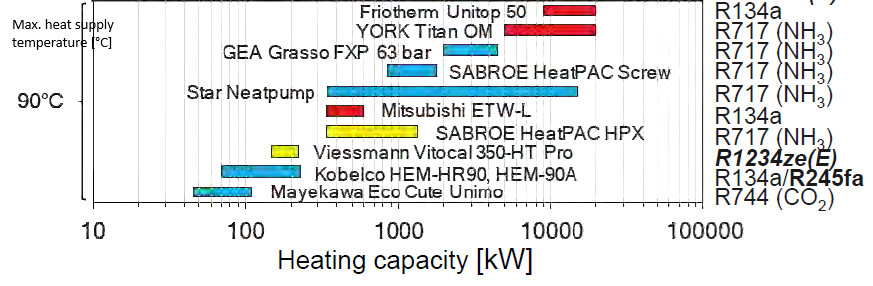

A selection of industrial heat pumps with supply temperatures of up to 90 °C (non-exhaustive list) Source: Arpagaus [3]

Are heat pumps that supply heat up to 90 °C state of the art?

Arpagaus: Yes, ammonia heat pumps (refrigerant R717) are an established technology. Equipment is available in this area from various manufacturers.

We use the maximum supply temperature as a parameter to compare different products and present them clearly. The heating capacity is also a technical parameter that can be used for comparisons. This is how the product overviews that you can find above were created. However, the decisive factor for determining the efficiency of a heat pump is the temperature increase between the heat source and the heat sink.

In the latest overview, which you presented at a conference in Bern in June 2024, the heat pumps you listed now reach temperatures of up to 280 °C.

Arpagaus: The higher temperatures for heat pumps have arisen because steam-generating heat pumps are also being developed. But there always needs to be an application that makes sense. There are already vapour compressors that generate 200 °C or 250 °C vapour, but then the temperature of the heat source must also be high, otherwise this will not be efficient.

How did you create the industry overviews?

Arpagaus: Over the years I have built up good contacts with numerous manufacturers – there are around 50 companies. I have been following the industry for six years and my first book was published back then with the title “High-Temperature Heat Pumps” [1].

The expertise of our Institute for Energy Systems at the OST Eastern Switzerland University of Applied Sciences lies primarily in the field of heat pumps and refrigeration technology. We therefore have many different projects with companies and within the projects the current state of the art should always be represented. We therefore send questionnaires to the heat pump manufacturers, but also conduct personal interviews. Creating these overviews is relatively time-consuming because all the product-related data to publish must explicitly be agreed with the companies beforehand.

Where are large heat pumps currently used most frequently?

Arpagaus: Within the IEA Heat Pump Technologies Programme, we compiled an overview of 342 industrial heat pumps in 2020 [4]. More than 25 % of these systems are utilized in the food and beverage industry, including beer breweries, fruit juice producers, wineries, dairies, milk powder drying, ice cream, bakeries, abattoirs, etc. The heat sources used are waste heat from cooling systems, fermentation processes, waste water, exhaust air from drying systems or coolers from cooking, evaporation and distillation processes at around 30 °C to 70 °C.

However, large heat pumps with several megawatts of heating capacity are also increasingly being used in district heating networks. As of 8 May 2024, large heat pumps are already integrated into around 14 % (193 of 1428) of the heating networks recorded in Switzerland. The most important heat sources here include groundwater (58 systems), wastewater (46), near-surface geothermal energy (39), lake and river water (38), and air (12).

Where do you see the main market opportunities for large heat pumps in Europe?

Arpagaus: In principle, this technology should be supported in all European countries. However, it is also heavily dependent on the economic viability. Where electricity is cheap, the chances of heat pump projects being realized are higher.

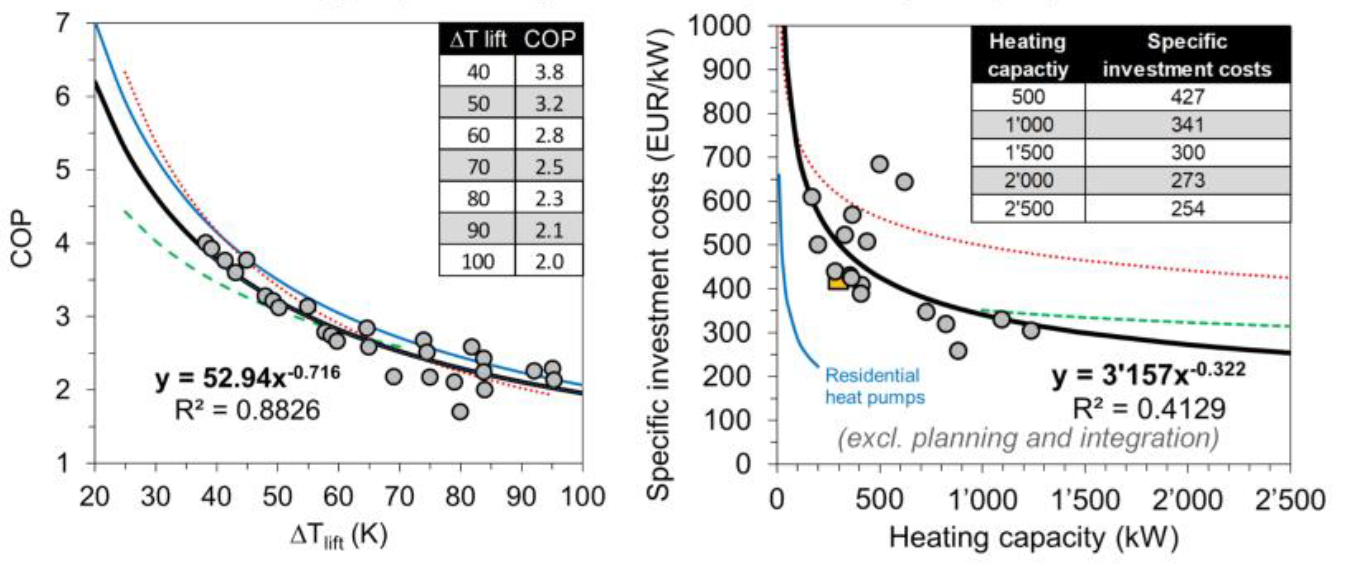

COP (Coefficient of Performance) values for industrial heat pumps at different temperature increases between heat source and sink (left) and specific investment costs for industrial heat pumps as a function of the heating capacity Source: Arpagaus [2]

You have worked intensively on the efficiency of heat pumps. Can you describe the left-hand diagram above in more detail?

Arpagaus: To characterize the efficiency of a heat pump, the COP under certain operating conditions is crucial. It is influenced by the temperature increase – the difference between the outlet temperature of the heat sink and the inlet temperature of the source. In the diagram on the left, we show the COP for various heat pumps as a function of the temperature increase. The fit of the curve in this diagram corresponds well to a Carnot efficiency of about 45 % to 50 %.

What is the Carnot efficiency?

Arpagaus: The Carnot efficiency describes the ratio between the real achievable COP and the theoretical maximum COP according to Carnot. The Carnot efficiency is very important for measuring the efficiency of a system. Using this diagram, we see that most industrial heat pumps achieve a Carnot efficiency of at least 45 %, i.e. the COP at a certain operating point is about half of the maximum Carnot efficiency. The average COP is around 3.0 and is achieved at an average temperature increase of 60 Kelvin.

Is there already a standard for determining COPs for industrial heat pumps?

Arpagaus: The manufacturers develop the industrial heat pumps for a specific customer with certain operating points that are important for the industrial process. The manufacturers then prove a COP in their test laboratory. There are tendencies towards a standardized procedure here, but there is still no definition of a standard procedure for determining the COP of industrial heat pumps.

Can you explain in more detail how the costs are shown in the diagram on the right?

Arpagaus: We received indicative offers for heat pumps from various manufacturers for specific planned projects and have presented them here in an overview in relation to the heating output. We wanted to show that there is a certain “economy of scale”, i.e. that the costs decrease as the heating capacity increases.

Each company has its own cost curve as the costs depend on various factors such as the technology used or the level of temperature supplied. For an initial cost approximation, we decided to use only the level of heating capacity as an influencing factor.