Eco-Tech Ceram from France is about to commission its third commercial high temperature storage tank solution at Wienerberger, a brick and tile producer south of Paris. There, two Eco-Stock units with 2.3 MWh each save waste heat from the ovens to be provided to the dryers. Eco-Stock units store heat at 600 °C in ceramics in a fixed bed. The first plant with slightly smaller Eco-Stock units from the first generation has already been in operation since 2019 at another brick and tile producer Tegulys in central France (see photo). It was the first demonstration plant jointly funded by the French renewable agency ADEME and the local region of Nouvelle-Aquitaine. Eco-Tech Ceram was one of the 31 high-temperature storage solution providers that took part in a global survey in early 2024.

Photo: Eco-Tech Ceram

Tegulys profits in several ways from the high-temperature storage plant. “The Eco-Stock solution allows us to improve the energy efficiency of the firing process but also to increase our production capacity”, said Nicolas Ducrot, CEO of Tegulys, quoted in the references on Eco-Tech Ceram’s Website.

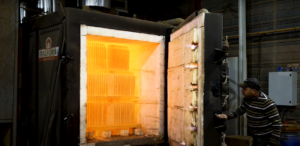

Before the Eco-Stock installation the company lost 50 % of its heat from the oven through the chimney. “We did a stitching on the chimney to lead the fumes into the two Eco-Stock units. As soon as the oven is turned on and the temperature is adequate, the ventilator will start and suck smoke through the pipes to charge the storages up to 600 °C”, explained Antoine Meffre, Founder and CEO of Eco-Tech Ceram in a film about this installation. When the drying process is turned on another fan pushes ambient air through the Eco-Stock units to be heated up and blown it into the dryers.

Oven at Tegulys for firing the dried tiles. Photo taken from this film: https://www.youtube.com/watch?v=Ma2bVMiWd_U&t=1s

10 % saving in fuel consumption for the whole factory

“Depending on the charge, the client can save between 90 and 100 % of the gas demand for the drying process and reduce his drying time”, confirmed Meffre. This means at least a 10 % saving in fuel consumption for the whole factory. The shortened drying time also increases production capacity. A win for both the environment and the profitability of the client.

The efficiency of the Eco-Stock units was checked after three years of operation. The discharging energy according to real data reached 1.21 MWh for one Eco-Stock unit at Tegulys. This is higher than the 1.19 MWh originally calculated before construction. According to Meffre the performance data was confirmed by the monitoring required by ADEME within the funding scheme.

Tegulys also profited from third-party financing. It has leased the storage plant from the investor BNP Paribas. The investment will be repaid via the leasing fee within five years, according to Meffre.

Efficiency boost at Villeroy & Boch in Southern France

The company lists two other commercial references with Eco-Stocks on its website (see table below). One Eco-Stock unit, for example, has been in operation at the ceramics factory of Villeroy & Boch in Southern France since October 2023. Here the energy efficiency measures looked like this: 11 aging dryers were replaced with 5 new, efficient units, which are now heated by recovering waste heat from the tunnel kiln. The client saves 3,000 MWh annually, 10 % of its energy needs.

“We need to reduce CO2 emissions. With Eco-Stock, a heat exchanger and third party financing solutions, Eco-Tech Ceram can offer industrial companies the possibility to reduce fossil energy consumption with no investment. The benefits are huge, but time is running”, Meffre made clear.

With a turnover of EUR 3.8 million in 2023 (an additional EUR 2 million in turnover will be recognised in March 2024 following the commissioning of the Wienerberger solution ) and an increasing workforce of currently 25 employees, his company is a well-established startup founded in 2014. Eco-Tech Ceram has two pillars. In addition to the high-temperature storage solution, it offers heat exchangers up to MW size.

Eco-Stock unit Photo: Eco-Tech Ceram

| Storage tank provider | Eco-Tech Ceram, France | Eco-Tech Ceram, France | Eco-Tech Ceram, France |

| Client name | Tegulys, France | Villeroy & Boch, France | Wienerberger, France |

| Number of Eco-Stock units | Two units of smaller size | One unit of larger size | Two units of larger size |

| Type of storage / storage material | Ceramics in a fixed bed | Ceramics in a fixed bed | Ceramics in a fixed bed |

| Operation mode of storage | Heat-to-heat | Heat-to-heat | Heat-to-heat |

| Maximum storage capacity | 2.4 MWh | 2.3 MWh | 4.6 MWh |

| Which application is stored heat used for? | Drying of tiles | Drying of ceramics | Drying of tiles |

| Heat transfer medium | Air | Air | Air |

| Range of temperature for operating storage | Ambient to 600 °C | Ambient to 600 °C | Ambient to 600 °C |

| Date of commissioning | 2019 | 2023 | Spring 2024 |

Key data for the three commercial plants with Eco-Stock units. A critical point in the table above is the maximum storage capacity information in megawatt hours. There is no standardized method to calculate the heat capacity of a high-temperature storage system and therefore numbers reported by each provider vary based on what calculation has been used. On this aspect, please also read the interview with storage expert Annelies Vandersickel. Source: company’s information