Two innovative heat pump projects in the megawatt range connected to district heating grids went into operation in Germany last year. The installations from Johnson Controls International (JCI), Denmark, and Friotherm, Switzerland, are both designed to provide hot water of up to 90 °C for their respective district heating networks. But that’s where the similarities end. Friotherm supplied the first heat pumps in Berlin, which utilize river water from the Spree as a heat source. JCI’s systems, on the other hand, are operated using ambient air as a heat source. The two projects also differ in terms of the type of compressor and refrigerant: JCI uses a two-stage piston compressor in its Sabroe series, while Friotherm utilizes a two-stage turbo compressor. JCI’s unit uses ammonia (R717) as a refrigerant, while Friotherm’s units operate with the synthetic refrigerant R1234ze.

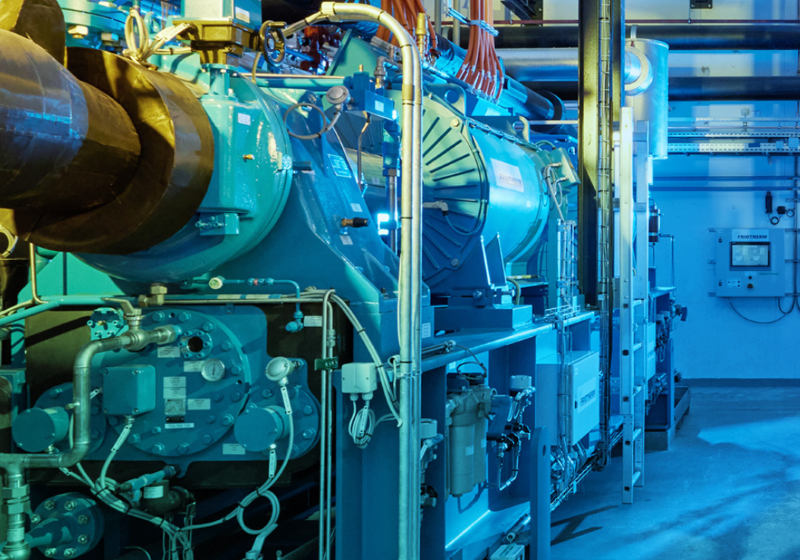

Photo: BTB

Friotherm’s customer is the E.ON subsidiary BTB in Berlin, Germany. At BTB, Managing Director David Weiblein is satisfied with the Unitop heat pumps, which have been in operation for just over a year: “The heat pumps have not caused any major problems so far. Since the end of the five-week commissioning phase, the two units have been running fully automatically.”

The large heat pumps extract some of the heat energy from the river water via shell and tube heat exchangers. In the second stage of the heat pump process, the temperature is then raised to the required level for the district heating network, i.e. to a flow temperature of over 90 °C. Finally, the Spree water, cooled by around 4 °C, flows back into the river through an outlet structure. The cooled water also has a positive effect on the river’s ecosystem by increasing its oxygen binding capacity, according to a press article published by BTB in August 2023.

“The heat pumps can be operated as soon as the river water has reached 8°C. We are therefore currently operating the systems from around April to November and have been able to achieve a coefficient of performance of 2.5,” confirms Weiblein.

“We designed and planned the two 3.5 MWth units individually for BTB at Friotherm’s Swiss headquarters,” emphasized Sales Manager Stefan Schwöbel. “The units were then built in our factory in Germany.” Friotherm is one of the few manufacturers in Europe using turbo compression.

The total thermal output of 7 MWth from the two custom-built heat pumps covers around a third of the customer’s summer heating requirements. They also form the renewable component required for the national subsidy scheme called Innovative Combined Heat and Power or iCHP (innovativen Kraftwärmekopplung, iKWK).

| Client | Blockheizkraftwerks, Träger- und Betreibergesellschaft mbH Berlin (BTB), Germany (subsidiary of E.ON) | Stadtwerke Heidelberg, Germany |

| Supplier of heat pump | Friotherm, Switzerland | Johnson Controls, Denmark |

| Type of heat pump | Water-water heat pumpel | Air/water-water heat pumps |

| Product type of heat pump | Unitop 28/22CY | Sabroe DualPac T716V/112LV |

| Electric power of heat pump | Two times 1.8 MWel | Three units of 455 kWel each |

| Total thermal capacity of heat pump | Two units of 3.5 MWth each | Three units of 1.35 MWth each |

| Date of commissioning | July 2023 | Installation in June and December 2023, commissioning not yet finalised due to technical problems |

| Type of compressor | Two-stage turbo | Two-stage piston |

| Type of refrigerant | R1234ze | F717 (ammonia) |

| Type and temperature of heat source | River water of at least 8 °C and up to 27 °C | Air of at least 5 °C |

| Temperature level of delivered heat | Up to 95 °C | Up to 85 °C |

| Coefficient of performance (COP) | ≈ 2,5 (at a heat supply temperature of 90 °C) | 2.2 (at air temperatures of at least 15 °C and a supply temperature of 90 °C) |

| Operation mode | Depending on river temperature, between April and November | Main time spring and autumn |

| Standard product or custom-made? | Custom-made system | Standard product with design specification |

Two heat pumps integrated into district heating networks. The COP of the project in Heidelberg refers to the heat pumps including the external air-water heat exchanger to extract the energy from the air. Source: manufacturers’ information

View of the Energy Park in Heidelberg, where the three air-water heat pumps of 1.35 MWth each started operation in June and December 2023. Due to some problems the commissioning of the units has not yet been finalised. Photo: Stadtwerke Heidelberg

Largest air-to-water heat pump system in Germany

JCI’s customer is the local utility company Stadtwerke Heidelberg in southern Germany where three air/water-water heat pumps of 1.35 MWth each were installed in the second half of 2023. “We are the first in Germany to have built an air-to-water heat pump system of this size,” Tobias Enders, project manager at Stadtwerke Heidelberg, is quoted as saying in an article in the online magazine Bayern Innovativ. “Ammonia is used as the refrigerant as it is more efficient than CO2, for example.”

The decision in favour of this system was made due to the small land area that these systems require. There was not enough space available for geothermal boreholes or solar thermal energy at the energy park of Stadtwerke Heidelberg and the Neckar river was too far away from the site.

For each of the three heat pumps around 500,000 m3 of air is circulated per hour. The outside air is sucked in by 180 turbines (60 per unit) and forced into the air cooler. The air is cooled by 5 °C and the heat recovered is fed into the brine system of the water-water heat pumps. The energy is then supplied to the district heating network via heat exchangers.

“At temperatures of below 5 °C, the heat pumps can no longer be operated, otherwise they would freeze,” explains Enders in the Bayern Innovativ article. Above around 15 °C, the heat pumps have a COP of 2.2 and are then efficient enough to be used in Heidelberg’s heating network.

Three towers with a diameter of 4 m blow the cooled air out at a hight of around 17 m. Photo: JCI

The key component of the Sabroe series from JCI is the piston compressor, which was developed by JCI and is manufactured in Denmark. The piston compressors ensure high pressures of over 60 bar so that the desired high outlet temperature of up to 90 °C is achieved at the condenser.

Recently, JCI has expanded its range of heat pumps through company acquisitions. In January 2023, JCI acquired the Danish company Hybrid Energy, which uses a combination of adsorption and compression process to reach sink temperatures of more than 100 °C.