The inauguration of the 30 MW parabolic trough plant at the Heineken factory in Seville, Spain, on 30 September 2023 was exactly on time. The investor and plant operator Engie España had to put the plant into operation before the end of September in order to receive the extensive subsidy of EUR 13.4 million from the European Regional Development Fund. With its 30 MW it is the largest solar industrial heat plant in Europe. It is followed by two flat plate collector fields – 10.5 MW in Nibbixwoud, Netherlands, for the Mol Freesia farm and 10 MW for Boortmalt´s malting plant in Issoudun, Southern France. A week after the inauguration a group of experts from the IEA Solar Heating and Cooling Programme visited the enormous installation (see photo).

Photo: Alan Pino Araya / IEA SHC Task 64

“This flagship project opens doors to industries that until now did not believe it is worthwhile to look into solar heating technologies”, Andreas Häberle is convinced. He is Chair of the IEA SHC Task 64 on solar process heat, which organized the technical tour to Heineken’s SHIP installation. Engie España signed a 20 year heat delivery contract with the client. According to a press release sent out by Heineken Spain on the day of the inauguration, the solar heat from the parabolic trough field will cover 50 % of the factory’s heat needs and delivers hot water at 210 °C and 25 bar to the energy grid of the manufacturing sight.

The Belgian turnkey SHIP project developer Azteq with its German subsidiary Solarlite and its Spanish office played a pivotal role in designing and implementing the heat power plant. The construction was carried out in a record time of twelve months, far quicker than the initial forecasts, which were for almost double this period.

“This project could be replicated in any other industry that meets the requirements and needs heat for its processes. It also confirms the position of Spain as a pioneer country in the implementation of this kind of decarbonizing industrial heat initiative,” summarized Peter Vandeurzen, co-founder and Business Development Director of Azteq.

The facility has a number of special features:

- The parabolic troughs are identical in size and structure to those of large concentrating solar power plants for electricity production (12 m x 5.77 m).

- The major components – receivers and mirrors – were shipped from China; the entire installation work was carried out by an Andalusian company.

- The solar circuit is filled with pressurized water, thus avoiding the use of environmentally precarious synthetic oils.

- The storage volume consists of eight stratified, pressurised steel tanks with a total volume of 800 m3.

“While the operation of large concentrating collector fields is well known from CSP plants, the integration of the eight large, pressurized water storage tanks is a milestone for solar process heat and is certainly an interesting area for further investigation”, commented Häberle after the technical tour. He also stressed the fact that the technicians from Heineken who led the tour were convinced of the technical maturity of the facility, which saves Heineken a lot of money.

Heat purchase agreement for 20 years

The contract between Heineken Spain and Engie España has different aspects. Engie is the investor of the EUR 21 million. Heineken Spain provided the 8 hectares of land for the parabolic trough collector field and the storage tanks. The companies agreed that Engie will provide completely renewable heat at a previously agreed price and when the agreement is 20 years old, the solar thermal plant will become the property of Heineken.

The Heineken plant was built in an extremely short time of 12 months. “Such an extremely short construction period for an installation on a power plant scale was only possible thanks to the above-average commitment of all teams, both from the suppliers and from the Azteq Group”, emphasized Joachim Krüger, CEO of Solarlite, Germany. “Our own supply chain and production capacity provide the security and delivery capability to execute projects in a short time”

The land area requirement for this project was around 2,700 m²/MW of installed solar thermal capacity, even including the large storage tank facility. “As there is usually a restricted availability of land around industrial companies, we arrange the rows of parabolic trough collectors as close to each other as possible. A rule of thumb here is two square metres of land area for one square metre of aperture area,” explained Krüger.

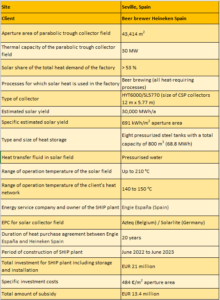

Key figures for the solar industrial heat plant in Seville. The subsidy was provided by the European Regional Development Fund (ERDF) and managed by the Institute for Energy Diversification and Saving (IDEA) Source: Azteq / Solarlite

A high-ranking visitor from Madrid came to the inauguration – Pedro Sánchez, President of the Government of Spain (second from right). He is accompanied by Carmen Ponce, Director of Corporate Relations and Sustainability of Heineken Seville, and Loreto Ordóñez, CEO of Engie España (first and second from left in first row), as well as Etienne Strijp, President of Heineken Spain (on the right). Photo: Heineken Spain

3.5 MW linear Fresnel field being commissioned at Heineken Factory in Valencia

The heat delivery contract takes Heineken Spain a big step further towards its internally set climate protection goals. According to a press release, Heineken aims for full decarbonization by 2025 and anticipates that by the end of 2023 renewable sources will provide 50 % of its heat and electricity needs and then 62% at the end of 2024.

“At Heineken we were pioneers in introducing sustainability in the beer sector more than two decades ago. Today we are again pioneers, with the help of Engie España, with this totally innovative project that positions Spain in a prominent place in the energy transition”, said Etienne Strijp, President of Heineken Spain, according to the press release.

Besides the SHIP system in Seville, Heineken lists a number of other renewable energy systems that guarantee the fulfilment of the targets. A 3.5 MW linear Fresnel system is being commissioned at the Heineken factory in Quart de Poblet in the province of Valencia. Here, the Spanish company CSIN is the turnkey supplier of the solar field and signed a steam purchase agreement with the client. Furthermore, a PV system is installed at El Andévalo in the province of Huelva, the production of biogas is planned at four factories in Spain and the manufacturing sight at Jaén will get a biomass boiler.