Typically, simplicity equals low costs. But the creators of a multi-technology thermochemical energy storage system for Gen3 concentrating solar power (CSP) claim that their complex design would bring costs down by enabling the delivery of solar energy not just within a day or two like today, but whenever needed, weeks and months later.

Compared to the cost of the Gen3 CSP plant itself, adding the thermochemical storage and the hydrogen production reactor barely increased plant costs, but added significantly more value by greatly expanding storage duration.

This dual thermochemical energy storage system would pair with the advanced CSP pilot plant being built by Sandia at its heliostat testing center in New Mexico as the US Department of Energy Gen3 CSP award winner.

Sandia’s Gen3 pilot, which broke ground recently, comprises a free-falling particle receiver feeding high-temperature particle storage. These sand-like particles heat up supercritical-CO2, a highly efficient working fluid run in a closed Brayton cycle loop.

To deliver after dark, today’s commercial CSP stores solar energy in molten salt. Sandia’s Gen3 pilot instead uses particles, which remain stable at much higher temperatures for greater efficiency. This supplies solar energy from thermal storage, typically for 8 or 10 hours.

But a new study from Arizona State University (ASU), where Prof. Ellen Stechel leads rigorous research in solar thermochemical potential, showed that the LCOE could be lowered by adding a pair of thermochemical redox cycles which can then deliver energy on any day it is needed, even months later.

“The novelty in our system is that we propose three levels of storage for a year-round guarantee of dispatchability,” explained ASU assistant research scientist Alberto de la Calle.

De la Calle revealed the outline of the novel concept in a presentation and abstract Techno-economic Analysis of a High-Temperature Concentrated Solar Power Plant with a Multi-Level Storage System for a Year-Round Guaranteed Dispatchability at the recent SolarPACES Conference.

The idea is to add two more levels of thermal energy storage to the one that discharges daily, one to do so up to a week later, and one to deliver energy on any day needed, even months away. For all three technologies, different methods would store and release energy. And rather than relying on one heat input for each type, there are multiple options for charging.

While the daily electricity delivery would run off stored heat like in today’s commercial CSP, the researchers take a unique approach to charging weekly and seasonal thermal energy storage.

The two additional systems center around a synergistic pair of thermochemical cycles, one to store long-term heat chemically and one to produce hydrogen.

Thermochemical energy storage schematic IMAGE@Techno-economic Analysis of a High-Temperature Concentrated Solar Power Plant with a Multi-Level Storage System for a Year-Round Guaranteed Dispatchability

Existing daily storage (Level 1) in the Sandia Gen3 CSP. Particles store “sensible” heat (the heat you can feel):

The hot particles in the Gen3 thermal energy storage tank are heated by the concentrated solar flux from Sandia’s test field of solar heliostats as they fall through the receiver. The heat is transferred to supercritical carbon dioxide to run an s-CO2 turbine to generate electricity. The particle storage tank is sized to hold a day’s supply.

For weekly storage (Level 2): Add storage in thermochemical heat:

A continually cycling thermochemical process would generate heat in a two-step redox cycle of a metal oxide thermally reduced with heat (charging) and oxidized in air (discharging).

“One of the purposes of this project is to find which is the most suitable metal oxide for this process. We have started testing CaAl0.2Mn0.8O3, a perovskite that has already been used in these types of cycles,” de la Calle said.

This Zigzag Flow Reactor for thermochemical energy storage would have three optional charging modes. It could be run with heat from the thermal storage tank and off-peak electricity, with only off-peak electricity (when the price is low), or by chemically reducing it with hydrogen produced on-site.

“This storage is also in particles. However, these particles are not chemically inert,” he explained. “When heated up to 1000 °C in a low oxygen environment, they react by releasing oxygen from its lattice. They are stored in a tank. When this storage needs to be used, the particles are mixed with oxygen. A second reaction, re-oxidation, then takes place, which releases heat. This storage would have similar capacity as the Gen3 storage, but the energy density is higher and storage time will be longer – of the order of the week.”

To recover the heat stored in this reduced metal oxide, a special heat exchanger from particles to s-CO2 has been designed in which the re-oxidation reaction would take place.

For seasonal storage (Level 3): Add a hydrogen reactor:

Hydrogen would be generated onsite in Labyrinth Reactor at ASU, a next-generation thermochemical design presented at the SolarPACES Conference for splitting water and carbon dioxide, running on off-peak grid electricity.

“In this reactor, the reduction reaction is around 1500 °C, and the re-oxidation reaction, if we use ceria as the metal oxide, is around 1000 °C,” said De la Calle.

“The difference from the Level 2 storage is that here the re-oxidation is with water (steam). The reduced metal oxide in the presence of water is able to release hydrogen by extracting the oxygen from the water molecule.”

Once the hydrogen is produced in this reactor, it is stored in a vessel until needed to drive the reduction reaction in the Level 2 thermochemical storage – and ultimately delivered to the grid through the s-CO2 cycle power block. This Hydrogen can also be sold as a commodity to the grid.

The counter-current configuration of the two thermochemical reactions maximizes the chemical potential utilization of the metal oxide used as redox material.

Results: Net earnings from generation from Level 3 thermochemical storage are highest IMAGE@Techno-economic Analysis of a High-Temperature Concentrated Solar Power Plant with a Multi-Level Storage System for a Year-Round Guaranteed Dispatchability

This team showed that their system could produce at least 8 hours of solar electricity every day, year-round, summer or winter, regardless of daily sun hours.

“This system offers unique flexibility, where we can buy and sell electricity when it is most convenient and sell hydrogen as a commodity to offset the operational and capital costs. The hydrogen revenue alone, net of off-peak electricity cost, compensates for CapEx,” he explained.

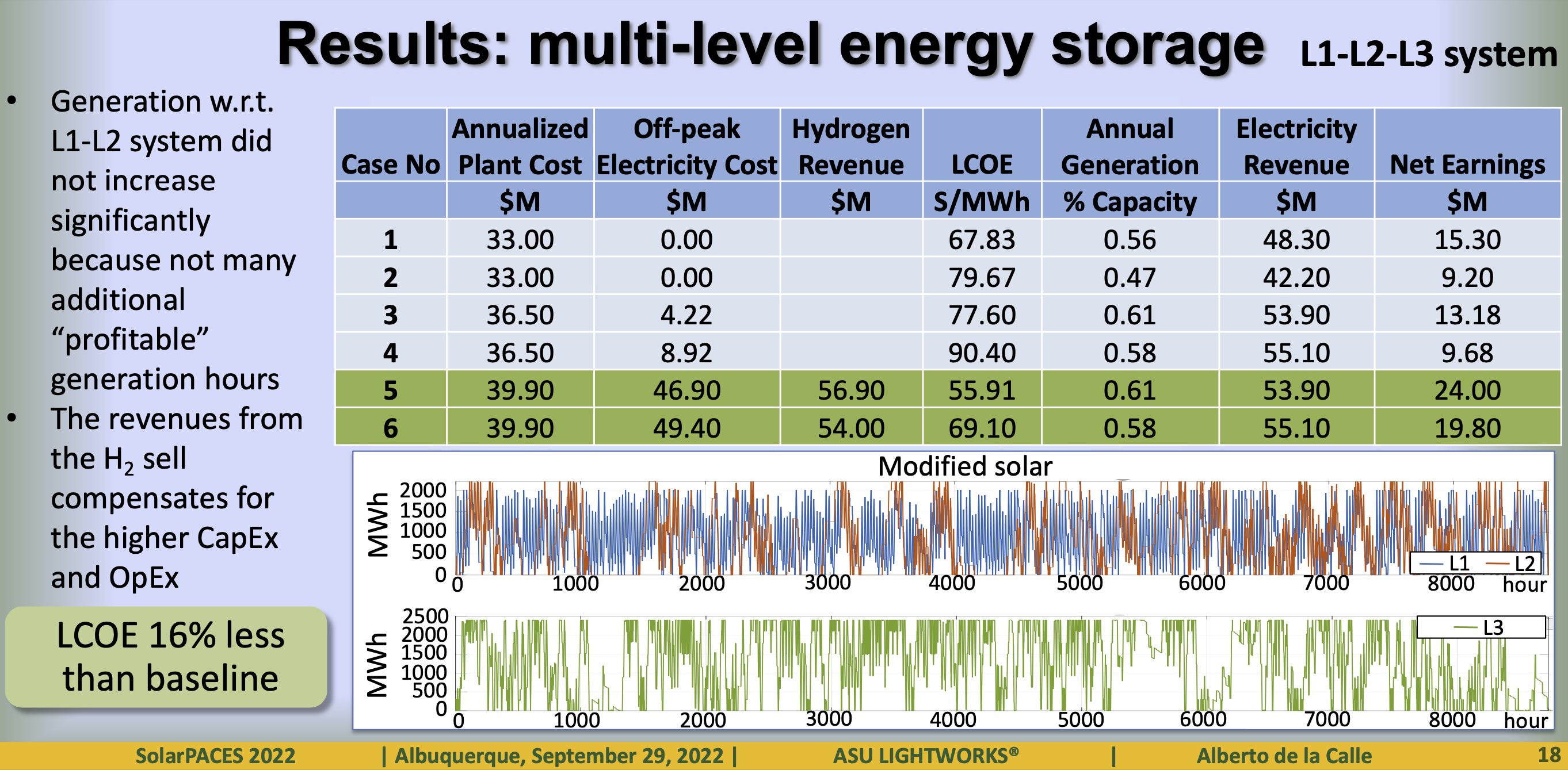

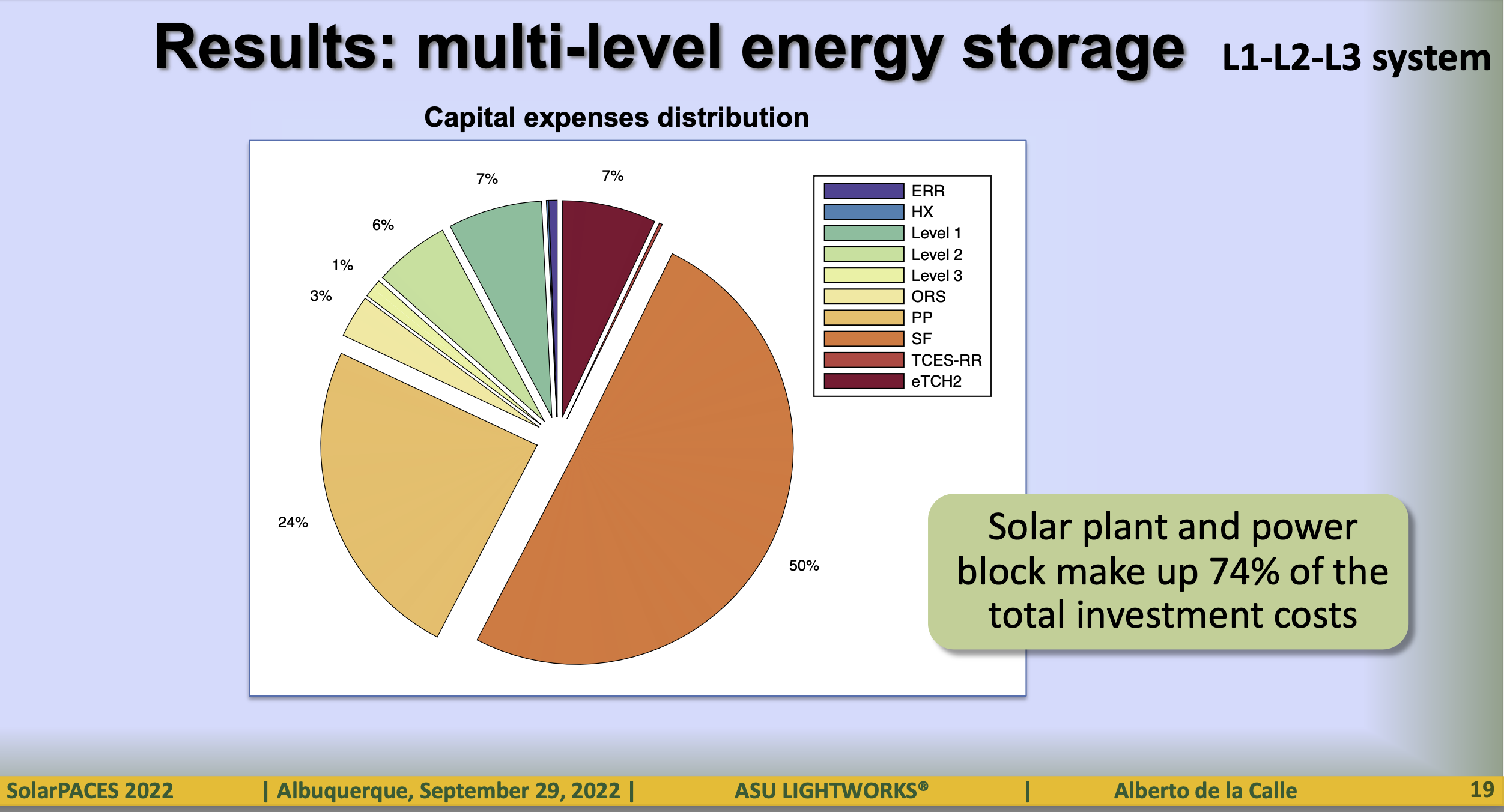

Compared to the cost of the Gen3 CSP plant itself, adding the thermochemical storage and the hydrogen production reactor barely increased plant costs but added significantly more value by greatly expanding storage duration.

Compared to the cost of the Gen3 CSP plant itself, adding the thermochemical storage and the hydrogen production reactor barely increased plant costs but added significantly more value by greatly expanding storage duration.

“To compare our multilevel storage system with a reference case to see if our system is better or worse, we calculated the LCOE of the CSP plant with only daily storage, with different solar multiples and different storage capacities as the baseline. And not only do we reduce the system LCOE, but we also guarantee year-round dispatchability.“ de la Calle said. “We found the LCOE of our three-level system is 16% less than baseline.”

It was the relatively little additional cost to add the two (Level 1 and 2) thermochemical storage systems that delivered the more valuable weekly and seasonal storage that was the key to this LCOE reduction.

More reading:

“Development and testing of the Zigzag Flow Reactor for thermochemical energy storage” Rhushikesh Ghotkar, SolarPACES Conference 2022

“Development and Testing of the Labyrinth Thermochemical Reactor for Water/CO2 Splitting at ASU” Ivan Ermanoski, SolarPACES Conference 2022

Evaluation of Alternative Designs for a High Temperature Particle-to-sCO2 Heat Exchanger C.Ho et al., Journal of Solar Engineering, 2019

Thermodynamic Analysis of a Reactive Particle-to-sCO2 Heat Exchanger for Recovering Stored Thermochemical Energy s-CO2 Europe Conference proceedings, 2023