For solar thermal systems to make solar fuels or provide industrial heat at temperatures at 1500°C, various designs for high-temperature solar receivers are being innovated to capture and convert concentrated solar heat directed from a solar field of heliostats.

IMAGE@Casati et al. A water-cooled hot solar window from A Solar Receiver Delivering Heat at 1500℃ and Above- Experimental Results – presentation.

Many designs for high-temperature solar receivers need a window to contain or pressurize the chemical reactions or fluids inside. However, this window gets very hot, compromising the system’s reliability and durability. So one challenge is how to protect the quartz window. Among the most critical issues in this sense are window contamination – for example, from sublimating components which re-condense and adhere to the window) and its devitrification, the damage caused by repeated heating and cooling.

A water-cooled hot solar window

A solution to making these receivers more robust would be to find a way to keep just the window from exceeding certain temperatures. “So that was the starting point of my research; how can we make these receivers more robust? How to keep the window colder,” said Research Associate Emiliano Casati, who tested his ideas at the ETH laboratories in Switzerland under the direction of the high-temperature solar fuels pioneer Aldo Steinfeld.

DWR water-cooled hot solar receiver window IMAGE@Xasati et al

The high-flux solar simulator at ETH delivers concentrated radiation to mimic the radiative heat transfer characteristics of highly concentrating solar systems using an array of Xe-arcs.

The goal was to find a way to ensure that the quartz window never exceeds 300°C, despite temperatures above 1500°C in the receiver, while achieving a thermal efficiency of over 50%.

He explained that while it is possible to work with the window at high temperatures in a lab for a short period, long-term decarbonization requires robust, reliable, and long-lasting systems that can withstand the high temperatures over time. The design needed to be scaled up for full-size and long-duration use in commercial projects.

To avoid devitrification, maintain a layer of liquid over the quartz window during operation

Quartz glass used in the window undergoes modifications at temperatures as low as 300°C, making it necessary to keep the window temperature below that threshold to extend its operating life. So his design aimed to minimize devitrification by controlling the window temperature to never exceed 300°C.

During the most recent international SolarPACES Conference, Casati showed photos and performance graphs of the two designs he demonstrated at the lab bench scale in his presentation of the results, in A Solar Receiver Delivering Heat at 1500℃ and Above- Experimental Results – presentation.

Casati’s initial concept was the Free Water Layer Receiver (FLWR), in which the water runs freely down the inside of the receiver window.

“This water is also evaporating and then providing some steam,” he explained.

“This steam is then superheated to very high temperatures, up to 1600°C, by flowing through a porous ceramic absorber directly illuminated by concentrated solar radiation. The absorber gets very hot and reradiates infrared radiation towards the window. This is the main mechanism causing the window overheating and a large share of heat losses to the ambient. However, the water layer we maintain on the window captures most of this “escaping radiation,” with the simultaneous effects of preventing overheating and reducing heat losses. It also prevents particles inside the receiver from sticking to the window, causing deposits and triggering hot spots and eventually window failures.”

In this case, Casati envisions that the heat transfer fluid or one of the reactants inside the receiver would also be steam. He suggested that there could be an optional separate inlet for injecting another gas or reactant inside.

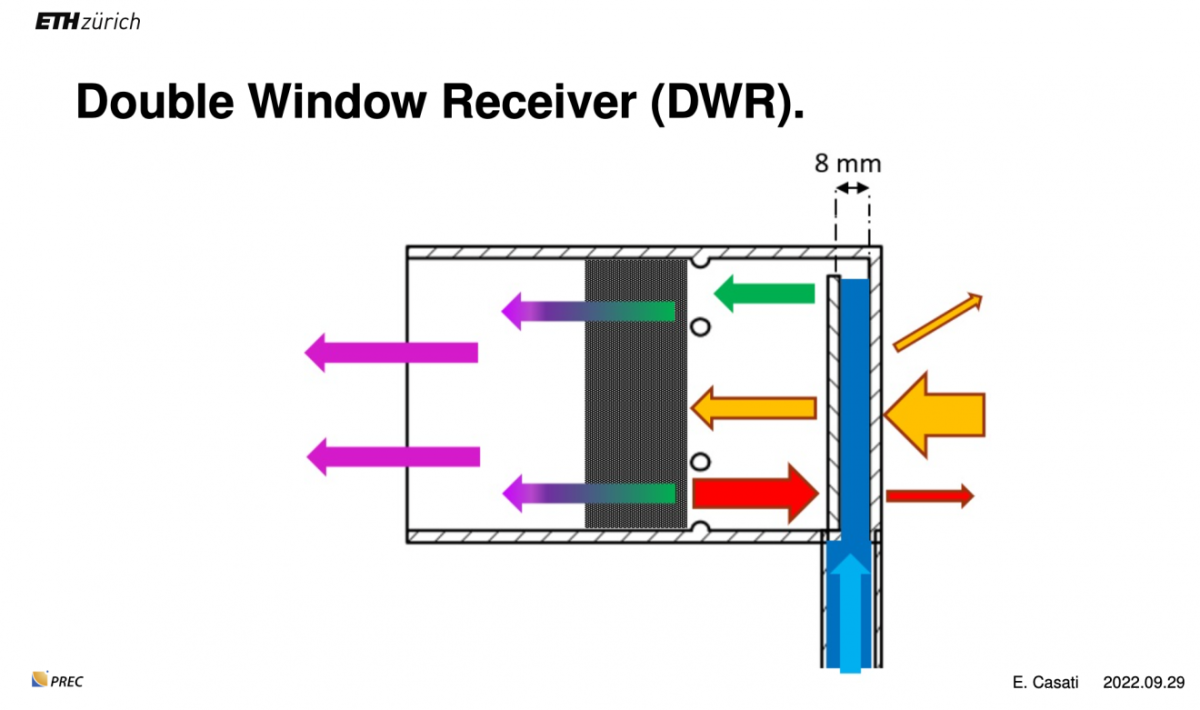

The next concept was a Double Window Receiver (DWR), where the liquid layer is confined between two quartz layers. The receivers were tested at different power input conditions and thus concentration ratio (the solar power flux reaching the receiver aperture and expressed in “suns,” normalized to 1 sun = 1 kW/m2).

Comparing thermal efficiency and temperatures achieved of DWR and FWLR with some previous research in CST or developed CSP projects IMAGE@Casati et al

The results

FWLR Receiver

solar concentration ratio: 2400

thermal power input 1368 watts

steam generated at 1519°C

thermal efficiency was 45%

window kept under about 150°C

DWR Receiver

solar concentration ratio: 3800

thermal power input 4774 watts

steam generated at up to 1612°C

thermal efficiency of up to 81%

window kept under about 160°C

During the preliminary tests, both designs achieved the goals of delivering steam at temperatures over 1500°C while keeping the window below 300°C and with thermal efficiency that ranged up to 81%.

The DWR’s higher thermal efficiency compared to that of the FWLR resulted from the increased thickness of the water layer allowed by enclosing the water channel between two layers of quartz. This is also expected to improve the absorber’s shielding and thus reduce re-radiation losses.

The future

This novel concept for keeping the window cool by using a layer of water to keep it below 300°C has the potential to help improve the design and development of high-temperature concentrating solar receivers. Casati and coworkers have filed a patent application and have been contacted by companies interested in licensing.

Susan Kraemer, solarpaces.org