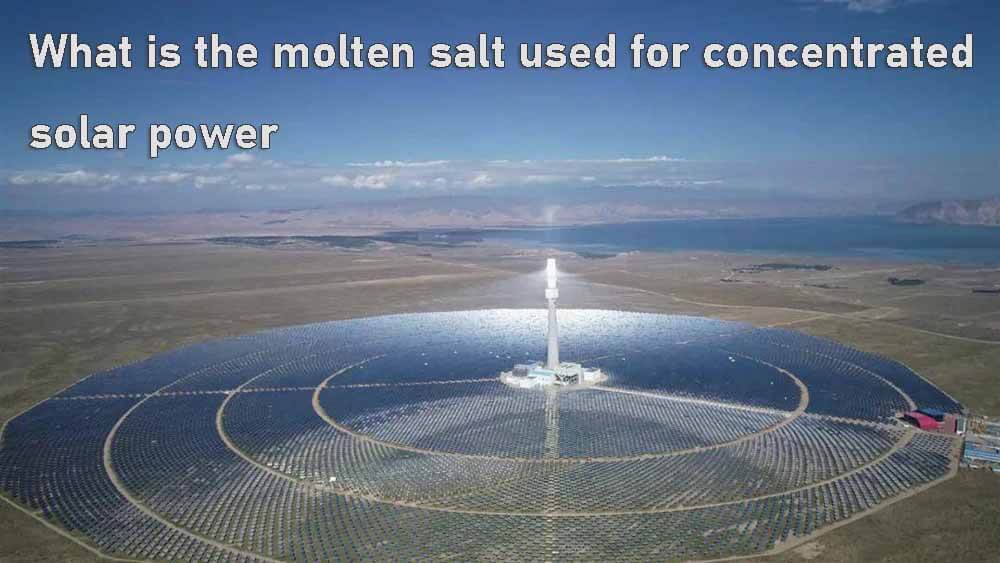

The concentrated solar power station (CSP station) was first developed in 2012 and operates in parallel with photovoltaic power generation. Concentrated solar power is very important to make up for the intermittency of solar power generation.

Concentrated solar power can assume multiple roles of “base load power supply + regulated power supply + synchronous power supply”. In terms of energy storage, concentrated solar power has the function of peak regulation due to its own energy storage.

At present, China’s concentrated solar power station is the first to do centrally controlled solar energy. Concentrated solar power uses specular reflection to focus the heat of sunlight to a point, causing that point to heat molten salt, or heat transfer oil, then use molten salt, a high-temperature and high-heat medium, to exchange with water, the water becomes high-temperature and high-pressure steam, or superheated steam to drive the steam turbine, and then to stabilize power generation, such a basic process.

Photothermal is the use of mirror support to rotate, sunlight is vertically irradiated to gather light energy, and photovoltaic is diffuse scattering to collect light energy. At present, light and heat are mainly concentrated in the three north areas, and photovoltaics can be done nationwide.

Concentrated solar power station is further divided into tower type power station and trough type power station. At present, there are more tower type power stations in China. Tower type power station is the kind that we can see a pillar with many mirrors around. The efficiency of the trough power station is lower, because it uses heat transfer oil and molten salt. The heat transfer oil has a maximum temperature of 400 degrees, and the specific heat effect is worse. Now the mainstream is to use the tower type.

Photovoltaic has no heat storage or energy storage device. It needs to be equipped with an energy storage device. This device may be concentrated solar power, pumped water storage, air energy storage, or electrochemical energy storage. For example, offshore wind power, there is a concentrated solar power station next to the wind power plant. Add a heater to the concentrated solar power, so that the wind power starts at night, the electric heat is converted, and the heat is converted into the molten salt, and the heat is exported.

Concentrated solar power is to deal with controllable green renewable energy, but after adding electric heaters, it is a large energy storage power station for the power grid in addition to being controllable. Photovoltaic is the same. Photovoltaic has electricity that abandons light. I want to save the conversion of electricity and heat, so that the concentrated solar power station has changed from a pure power station to a huge energy storage station.

The electricity generated by photovoltaics is unstable, and some of the electricity cannot be connected to the Internet. Then, an electric heater needs to be connected. The heater is inserted into the molten salt, and the molten salt is heated to a high temperature and stored in the molten salt tank. The larger the photovoltaic power station, the greater the power, and the greater the amount of molten salt tank and molten salt it is equipped with.

In terms of peak shaving range, concentrated solar power station is far superior to thermal power station. Assuming that thermal power and photovoltaic wind power are used in combination, the thermal power supply is 100, the wind power and photovoltaic are 50 each, and the current full load is 200, if the electricity load drops to 100, then the thermal power needs to be stopped on the premise that 50 of the scenery cannot be abandoned, but the actual situation is impossible.

The electricity load of thermal power can only be reduced to a minimum of 40%, so the scenery can only be abandoned. If 100 of the thermal power is replaced by solar thermal at this time, this does not need to be abandoned at all. It can be transferred to the molten salt through an electric heater and stored as energy. This situation is particularly evident in the winter heating season.

The molten salt composition is a mixture of 40% potassium nitrate and 60% sodium nitrate. The melting point is 220 degrees. It starts to melt at 220 degrees. After melting, it starts at about 260 degrees and can be circulated in the pipeline, it is circulated to the molten salt tower, and then absorbs solar heat. It can be heated to about 600 degrees. After 600 degrees, it is stored in the hot tank. After storage, it is released when power generation is needed.

Go to the heat exchanger, exchange it with steam, and then connect to the steam turbine to generate electricity just like a conventional power plant. The trough type is generally suitable for regional centralized power supply, and the trough type power station uses more molten salt. If it is used as energy storage for long-distance stable power supply, the tower type is better. At present, the tower type accounts for 60%, the trough type accounts for 30%, and the linear Fresnel accounts for 10%.

The relevant carbon peaking action plan is clear: actively develop concentrated solar power, and promote the establishment of a wind-solar integrated renewable energy power generation base with complementary adjustment of concentrated solar power, photovoltaic power generation and wind power. Other forms of energy storage cannot be promoted on a large scale due to factors such as geographical location (pumped hydro energy storage, air energy storage), low energy density (flywheel), and short life (electrochemistry).

The intermediate medium is molten salt, and the main components are potassium nitrate and sodium nitrate. During the reaction, potassium nitrate and sodium nitrate operate in a closed loop, and the annual loss is less than 1%, after 30 years of use, it will not deteriorate (the molten salt will not deteriorate, and there will be no chemical reaction, just a physical reaction).

Under the comprehensive calculation, the cost of energy storage of concentrated solar power is lower. In addition, concentrated solar power, as a peak-shaving power supply, has the advantages of flexible and adjustable output and long term energy storage, which will be able to win more benefits for the project through a market-oriented approach, thereby effectively supporting the sustainable development of China’s solar thermal industry.

Moreover, in recent years, regions rich in solar energy resources such as the Middle East and North Africa have begun to use concentrated solar power as a solution to continuously use renewable energy to generate electricity, using light and heat to generate electricity at night and shaving photovoltaic peaks during the day, concentrated solar power has good market prospects in these regions. At present, the speed of CSP approval is accelerating. This year, intensive bidding has been launched, and it is required to connect to the grid as soon as possible. The follow-up depends on the continuous efforts.

① Safety

The safety of energy storage is an important aspect of large-capacity energy storage, and heat storage with binary nitrate is a safe heat storage method. Since the SOLAR ONE in the United States in April 1982, the world’s 6.69 million kilowatts of solar thermal power generation has not experienced safety accidents such as lithium battery explosions, and it is a high-safety energy storage method. Due to the inherent charging and discharging working principle of lithium-ion batteries that are widely used at present, this type of electrochemical energy storage has natural safety hazards. So when choosing lithium ion solar battery, we need to choose odm lithium ion battery pack manufacturer with quality assurance.

② Economical

The cost of electrochemical energy storage is 800RMB/kWh + 200RMB/kW, the operating life is 10 years, and the annual operation and maintenance fee is calculated at 1%. The unit kilowatt investment of the concentrated solar power project is expected to be reduced to 22000RMB/kW~24000RMB/kW, the operating life exceeds 30 years, and the operating cycle cost and electricity price are lower than electrochemical energy storage.

③ Constructive

The site of the electrochemical energy storage power station should have convenient and economical transportation conditions, the connection with the road outside the station should be short and quick, and the amount of engineering should be small; The site should be close to a reliable water source, the site selection conditions should be coordinated with the local industrial planning, and the conditions are relatively easy to achieve.

The construction conditions of concentrated solar power are relatively harsh, with high atmospheric transparency, dry climate and little rain, long sunshine hours, and abundant solar energy resources. The annual direct solar radiation (DNI) in the site selection area should not be lower than 1600kWh/(m2∙a), and the site is open and flat without obstructions. Therefore, the Three North Areas are generally selected, but the land acquisition cost of the site is relatively low.

Taking the Delingha project as an example, it is about 50MW, 1.1-1.2 billion, equivalent to 22 yuan/W. The electricity price is 1.15 RMB. Purely independent solar thermal power station cannot do it, but now it can be used as energy storage for photovoltaics. For example, Qinghai photovoltaic on-grid electricity price is 0.25RMB. If it is equipped with CSP station, it will cost about 0.3RMB, and the price is slightly higher.

If only photovoltaic + molten salt tank is used, it will become pure molten salt heat storage, not Concentrated solar power station. This efficiency is very low. You can refer to the principle of thermodynamics – Rankine cycle. In this way, the conversion rate is only about 40%, which is equivalent to 100 kWh of electricity generated by photovoltaics, and finally only 40 kWh can be released. With the addition of heliostats, the demand for energy supplementation can be met and the conversion rate can be improved.

Heliostats are glass and silver, and heliostat manufacturers include Luoyang Glass and Ancai Hi-Tech. The cost of mirrors accounts for about 5% of the overall Concentrated solar power investment, 9% of the concentrating system, and brackets, which account for 9% of the concentrator, 15% of the controller, and 61% of the drive device.

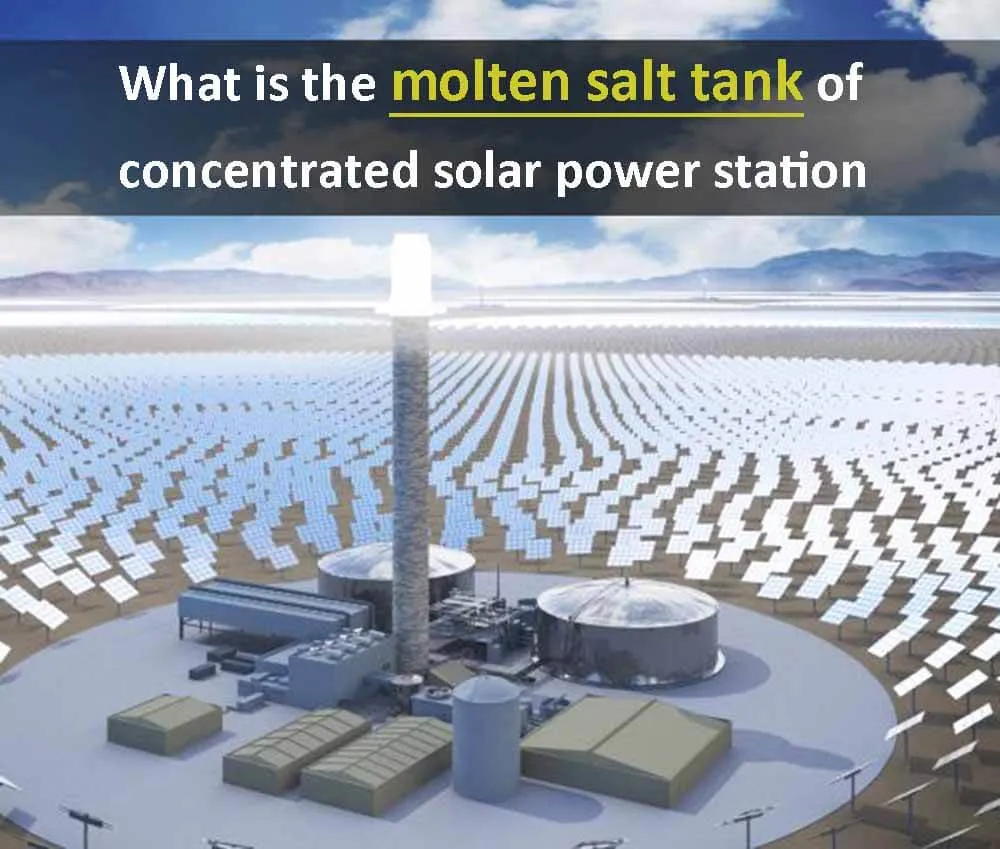

Molten salt + heliostat system (concentrating system) accounts for nearly 70% of the total investment, and molten salt generally accounts for about 20%, which depends on the design specifications. The amount of molten salt depends on how many hours the project maintains power generation. For example, the Delingha project is 50MW for 7 hours, then the molten salt tank and the amount of molten salt are distributed according to the 7-hour grid power generation. If it is 4 hours, it will be assembled according to the 4-hour amount.

The amount of molten salt of 1GW can be linearly extrapolated from the amount of molten salt used in the 12H design specification of 100MW, which is about 600,000 tons. This still depends on the size of a single project and the number of hours of utilization. 600,000 tons is an estimated value, which may require 500,000 tons or 700,000 tons. Now the price of sodium nitrate and potassium nitrate is about 6500-9000 RMB, it is estimated that the value of 1GW of molten salt is about 3.8 billion to 4.5 billion RMB , close to 5 billion RMB.

The molten salt tank is a storage tank. This is not difficult, because it is normal pressure and high temperature. 50MW needs about 4 tanks, two molten salt tanks, and two cold salt tanks, 25 meters in diameter and 22 meters in height. The material is ordinary high-purity steel . The light is collected to the collector above the tower. There is a molten salt tank in the collector.

The molten salt tank is the place where the molten salt is filled, because molten salt cannot flow once it solidifies, it must be kept above 260 degrees, and the melting point of molten salt is 220 degrees. After the molten salt flows out, it goes into the heat exchanger and transfers the heat to whom. After the water is heated at about 550 degrees and 13.2 MPa, it becomes steam to drive the steam turbine to generate electricity.

After the heat exchanger exchanges heat with water, the molten salt temperature drops and flows into the cold salt tank, and the molten salt whose temperature drops after the heat exchange is stored in the cold salt tank (This can still flow, because it will not be cold enough to solidify), and then pump it into the collector of the molten salt tower through the pump to become such a cycle.Such a project cycle can be maintained for 30 years. The molten salt is not denatured by physical changes, but there will be leakage, so some molten salt should be replenished regularly every year.