IMAGE@ A. Chinnici, University of Adelaide, Centre for Energy technology

Iron, nickel, alumina and copper mining processes are among the industrial processes that require heat at between 700°C and 1000°C. The advanced concentrated solar thermal (CST) reactors being developed by researchers globally can attain temperatures this high (and higher, up to 1500°C).

But CEOs in mining and mineral processing industries are more familiar with fuel combustion than with advanced solar fuels research. And they are a bit uncomfortable with how solar would supply the round-the-clock heat needed in that mining processes; using thermal energy storage in molten salts.

“They don’t like molten salts,” explained University of Adelaide Principal Research Scientist Alfonso Chinnici who works closely with them. “So they want something that is more robust, safer and simpler. Also, the temperatures required for some processes are well beyond what molten salts can offer.”

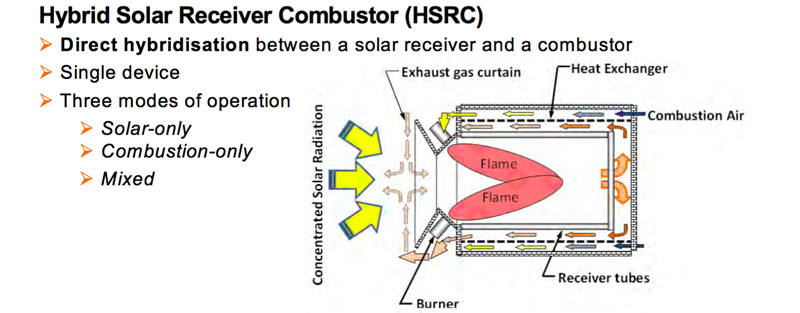

To accommodate their concern; Chinnici and professors Gus Nathan and Bassam Dally who direct the Centre for Energy Technology (CET) at the university, developed a solar “combustor” that can run round the clock as a hybrid able to mix heat from solar radiation coming from a heliostat field with heat from the combustion of any renewable fuels, including renewable syngas or renewable hydrogen.

The University of Adelaide is close to one of the biggest copper mines in the world, and has a practical industry focus. “We work really closely with big companies to actually make an impact with things that can be used in the real world” said Chinnici.

Working closely with companies such as Alcoa, BHP, GFG and OZ Minerals, the CET team has demonstrated at lab scale that their combination fuel combustor/solar reactor is fuel-agnostic: it can operate 100% on solar radiation or 100% by fuel combustion, or on any combination of the two heat sources, as a direct hybrid.

The HSRC Hybrid Solar Receiver Combustor IMAGE@ A. Chinnici University of Adelaide Centre for Energy Technology

“The economics looks really good. This is critical as big mining companies have a very high capital investment and very tight profit margin and they are all about CAPEX and OPEX. So, they don’t like changes. Since the combustor can also run on just the familiar fuel, there is a safety net: if something goes wrong they can revert to 100% fuel.”

Next step for the first direct hydrogen/solar hybrid

Earlier research internationally combined a solar receiver with a separate combustion unit, he said. But in these designs, the two devices performed indirectly – in series or in parallel.

“What we did is combine the function of these two devices in one single device that can harness the different energy sources at any time,” explained Chinnici. “Because indirect hybridization proved to be quite inefficient, and that’s why we looked at this new route.”

At the lab scale, using simulated solar radiation with high powered lamps, Chinnici’s team demonstrated that direct solar hydrogen combustion could reliably provide a firm supply of cost-effective round-the-clock 100% renewable heat, year-round, without storage.

“We have a 30-kW prototype that has been in operation continuously, so it has not been stopped for 7,000 hours and has been producing hot air at around 800°C all this time with no problem,” he explained.

“This device has been patented and we are ready now to go for what we call “on sun” testing,” said Chinnici. “Scale up the device to prove it in a larger setting; scaled to maybe 250 kW or 1 MW first and then maybe 5 MW. This could come from private investment from mining or from government agencies, such as ARENA. We are looking at the best funding scheme for this.”

The next step is outdoor testing at larger scale in a small heliostat field concentrating real sunlight up to the reactor atop a solar tower. If the large-scale demonstration of the solar combustor is successful, many other industries with high temperature industrial heat requirements like cement and steelmaking would have a proven fossil-free alternative. (Most mining firms need less than 10 MW.)

A model illustrating a typical ‘polar’ layout when a solar field is designed to supply concentrated solar flux to a solar fuels reactor atop a tower IMAGE @AdelaideNow.com

A “magic” combustor with fuel switchability

The direct hybrid design required what Chinnici called “fuel flexibility and switchability,” so the basis for the patented device is a commercially available state-of-the-art combustion technology used in material handling in the steel and glass industry: Moderate or Intense Low oxygen Dilution (MILD), that uses a completely different way of burning a fuel that is flameless.

For this process; to switch between the different heat sources at various times throughout every day and night, MILD has an ideal quality, it is completely fuel-agnostic, according to Chinnici: “It is pretty much a magic process, because with any fuel that you put in, the efficiency doesn’t change much.”

Because this “magic” device operates on any source of heat, it can efficiently switch from heat radiation from the solar receiver, to heat from radiation and convection from burning the hydrogen.

“The challenge was mostly from integration and combustion point of view because any burners that are out there work efficiently on a particular fuel; they don’t very much like any fuel change. When you change your fuel, you cannot achieve similar performance or even stabilize your combustion process, so the combustion process is very inefficient or dirty,” he said.

The result, as described in their paper; Performance Characteristics of a Hybrid Solar Receiver Combustor Utilising Hydrogen or Syngas and presented at the SolarPACES Conference in Morocco, was that:

Similar thermal performance, in terms of heat flux, efficiency (up to ~90%) and emissions (NOx < 15 ppm), can be achieved in the different modes, despite the different nature of the energy sources and their different heat transfer mechanisms.

The NOx emissions are close to zero because of the particular combustion technology selected. (The very small amount of NOx formed is because the combustion happens in normal air, which includes nitrogen.) The process is also very efficient.

“In this MILD combustion of hydrogen – even without solar – you increase radiation efficiency. The feature of this combustion process is you also increase the heat transfer rate. With a hydrogen fuel you have a ratio of up to 70% radiation and 30% from convection,” he explained. “That means the heat transfer from the radiation is very similar to concentrated solar radiation from a solar field, which is about 90% – or almost 100% – radiation.”

The solar/hydrogen combustor could also run on drop-in solar fuels

The fuel flexibility of the MILD combustor also enables it to be fueled with any syngas blends as well as pure hydrogen. “We also tested and proved that it can operate with blends. The performance are similar regardless of the fuel type,” said Chinnici. “Either hydrogen or hydrogen blends. We tested hydrogen and we looked at five different ratios of hydrogen and carbon monoxides – the syngas; all of these were similar.”

Solar syngas can also make solar jet fuel or solar gasoline by going through the Fischer-Tropsch process. Solar jet fuel would still emit CO2 when burned in an airplane, but they have about 30% less round-trip emissions than fossil fuels since they reuse CO2. Researchers say this “drop-in” technology is close to commercialization, while solar hydrogen is more dependent on a political commitment to switch infrastructure from fossil fuel delivery to hydrogen.

Drop-in fuels have a part to play even as the world moves to a carbon-free economy, because airplanes are designed with a 30-year lifespan; so models ordered last night will probably still be in the air in 2050. And gas cars on roads today will still be emitting CO2 in a second-hand market in 2030 even after their original owners have switched to cleaner EVs. In the US, over half of car sales are used vehicles.

A solar/hydrogen combustor could also make more renewable hydrogen

When solar hydrogen is made using CST heat, it can be produced either by splitting H2 from pure H2O – or it can even be extracted from “messier” renewable water sources like wastewater, produced water, or algae.

The focus of the research was mining processes that require temperatures of between 700°C to 1000°C, round the clock. But using CST to make hydrogen also requires a steady temperature around the clock, and despite seasonal intermittency in solar resource, with heat in the same temperature range, of up to 900°C. Both of these requirements are met in the solar/hydrogen combustor.

So in commercial operation, the solar hydrogen combustor could also prove to be the ideal technology to make more solar hydrogen.