Researchers at DLR, and NREL, and the Bill Gates-funded start-up Malta have been investigating converting coal plants into grid-scale thermal energy storage for curtailed intermittent renewable energy, as low-cost heat “batteries.”

Aalborg CSP’s steam generation system for the 600 MW DEWA Concentrated Solar Power project in Dubai

Conversion would repurpose most of a coal plant’s assets. Instead of burning coal for the heat, tanks of molten salts would be heated electrically by surplus PV and wind on the grid to “charge” the storage, which could then be “discharged” back to the grid on demand using the former coal plant’s existing power generation and transmission assets.

Now Denmark’s Aalborg CSP A/S has taken a first step to commercialization. Their Integrated Energy System (IES) department, led by Executive Vice President Peter Badstue Jensen now offers their retrofitting of coal plants into thermal energy storage commercially.

The firm’s wide experience in the design and development of complex solar thermal energy and storage systems includes technologies supplying district heating and solar thermal plants operating globally. These include the world’s first seawater desalination solar greenhouse in Australia and seasonal thermal energy storage in Tibet that covers 90% of Langkazi’s annual heating requirement.

IES Sales and R&D Manager Hammam Soliman presented the details at the SolarPACES 2020 Conference.

SK: Your Aalborg CSP presentation introduced a typical candidate for conversion to 4GWth thermal energy storage; A coal plant that produces 30% of Danish coal based CO2 emissions. Have you talked to these owners?

HAS: Yes, we presented the initial idea to them, and to several other coal fired boiler operators. They all showed interest in the idea, and the next step is to fully complete the financial analysis of the business-case. So, the next steps towards adoption, like seeking partial national funds to support the idea, will be initiated when the business-case is fully analyzed. We are working closely with universities all over Europe and they are also calculating this, but we believe that they are waiting for some kind of political decision; lowering electricity purchasing tariffs or at least some kind of regulation of the tariff system to benefit an energy storage market.

SK: So policies are needed?

PBJ: Currently, the economics of power generation from storage are profitable for generators of heat or electricity, but after taxes and transmission tariffs kick in, the profitability is lowered. What would help is lower taxes and tariffs for providing energy storage. Or higher CO2 taxes, as then the feasibility of making all green electricity – including storing it – improves significantly. Then the technology can also be implemented in the large industrial sector. The problem is that the business case is barely profitable when calculating on the clean spot market, without special regulations on trading income; times when grid operators pay extra premium for power supplied or at times when the price is lowered to well below the spot market in case of too much supply. When a balancing market is this unpredictable it is not possible to guarantee high yields for the investors.

SK: Are Danish coal plants going to be decommissioned anyway?

HAS: According to Denmark’s Climate & Energy Outlook, the expected phase-out of coal at Nordjyllandsværket will be at the end of 2028. The main plan in Denmark is to completely phase-out coal plants by 2030. However, with the recent decision to phase-out coal earlier at another coal plant, Fynsværket in 2022, the energy utilities use of coal in Denmark is expected to be fully phased-out before 2030.

SK: Might Aalborg CSP buy coal plants to convert them?

PBJ: Currently it is not the strategy or core business of Aalborg CSP to own and operate assets, but that could be an interesting path to consider for future expansion and growth. For now, we support owners, developers, and EPC contractors with everything from plant development, feasibility studies, detailed engineering and supply of complex integrated power and heating systems.

SK: Are there technical or logistical challenges?

HAS: There are no real technical challenges. They have already been solved or addressed in operating plants within the CSP sector. Through the years, our team has designed and developed custom-made solutions that address and focus on solving technical challenges thanks to our in-house R&D knowledge and the research institutions that we collaborate with. Any logistical challenges that are proven to be show stoppers do get detected during the feasibility studies. Developers and owners thus avoid wasting large sums of money on a project that isn’t feasible.

PBJ: Our philosophy is that energy is not religion. We work on all kinds of integrated energy systems from simple heat recovery to complex hybrid systems. Within renewable energy in general we work with a wide range of technologies. We are open to all technical solutions proven beneficial to our customers. Our extensive experience in energy system integration and optimization and in performance modeling and system design means we can find technical solutions to most constraints.

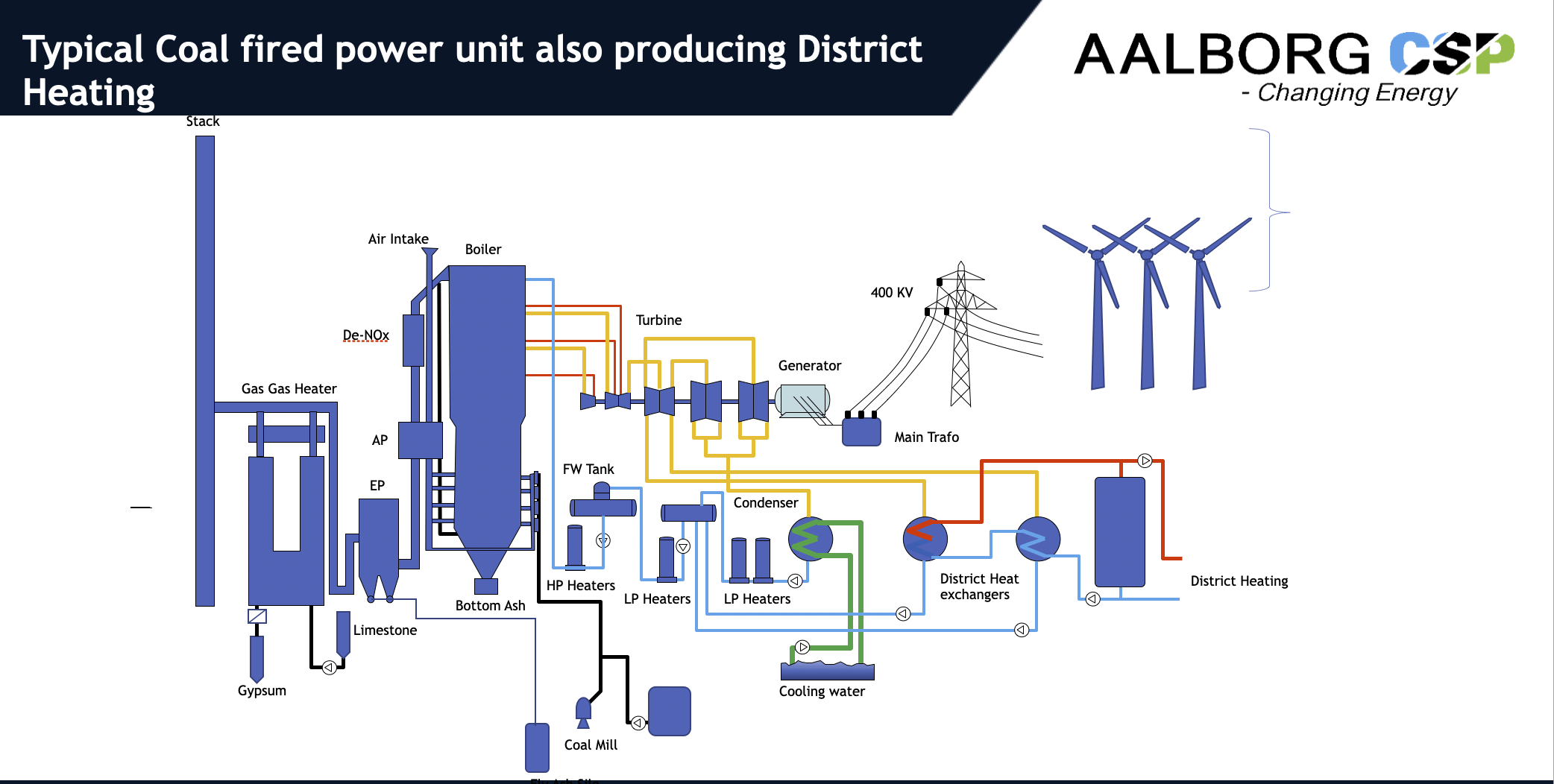

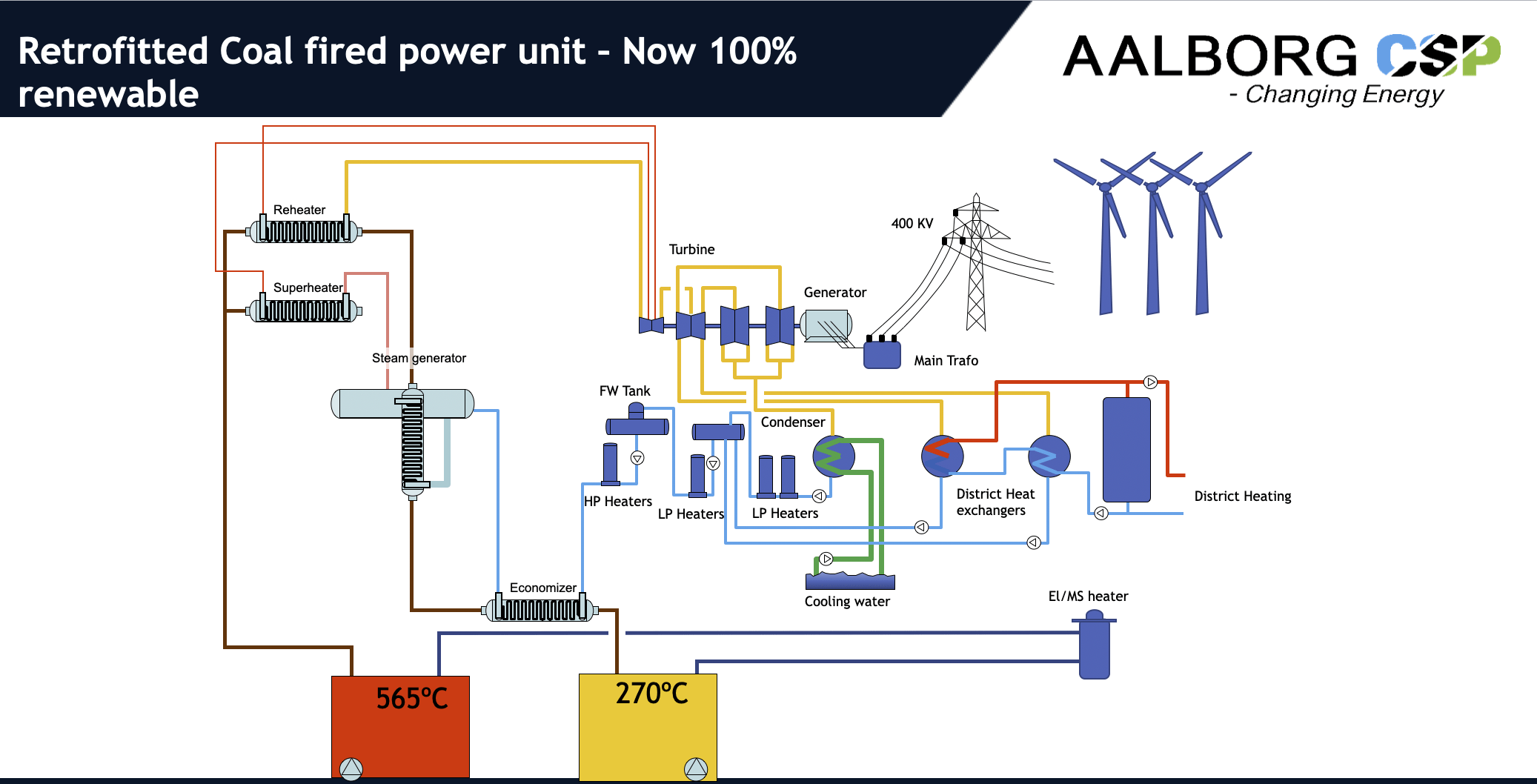

Before: Turning coal plants into modern renewable thermal power plants based on energy storage would repurpose all the assets except the coal fired boilers including all of their fuel and waste handling equipment. Most of the existing components of a coal fired power plant – the turbines, the generators, the electricity switch gear, transformer system and the transmission (both to/from the grid) – would all be utilized in a retrofitted version, to be able to operate in conjunction with a new thermal energy storage and steam generation system for the supply of ‘on-demand’ electricity to the grid.

After:The system works by charging (by heating up) molten salt pumped from a cold tank to a hot tank through an electrical heated salt heater, or directly from a molten salt heating CSP platform. The heat can then be stored with the only losses being the thermal losses from the surface depending on the layers of insulation of the tanks. At discharging (cooling down) the salt is pumped through a steam generator where heat of the molten salts is converted into high pressure steam, that can drive the existing steam turbine and produce electricity to the grid on-demand, powered by surplus PV and wind electricity.

SK: What existing components could you keep?

HAS: We could save and reuse most of the existing components of a coal fired power plant – steam turbines, generators, the high-voltage electricity switch-gear, the transformer system and the transmission to and from the grid, the water treatment plant, and the district heating system if applicable; like it is in Denmark for example. We would remove only the coal components, the boiler, chimney, flue gas cleaning and coal-related equipment. Then we would install our e-TES system. If preferred, our system could be installed in parallel with existing coal fired units for a “bump-less” transition, for the security of having a dual generation source during a coal phase-down period.

SK: Does Denmark need energy storage?

HAS: Yes. Denmark has 5.52 GW of wind power. When we have excess, we sell to neighboring countries like Norway and Germany, but when our wind supply is low, they supply our demand. But buying electricity normally costs many times more than the rate we get when we sell it. Of course, each country and plant has its special conditions and business case. We need a market mechanism to incentivize storage.

SK: Would permitting be difficult?

PBJ: For owners or operators of existing coal plants, transitioning to ‘green operation’ requires a minimum of additional permitting. The new operation mode only requires that the power plant make an agreement with the grid operator about buying and absorbing electricity from the grid at peak hours and for balancing purposes.

SK: What would make this bankable? The US offered government loan guarantees for the first utility-scale US solar farms for example.

PBJ: We are only using and proposing components of proven technologies, and each main component is already bankable alone, like CSP’s molten salt thermal energy storage technology, so the only real obstacle is that coal plant conversion has not yet been demonstrated. Therefore we must prove the future feasibility, the rate of return for investors over the plant lifetime. For financing institutes like banks or pension funds to invest, they require a guaranteed high return of the investment.

SK: Who might fund this first demonstration plant? It is completely new to convert a coal power plant to store renewable electricity. Yet the global potential’s so enormous.

HAS: EU programs like Horizon2020 and EU-GreenDeal are the most common funding sources that we apply for or participate in applying for in collaboration with other institutions or owners. However, EUDP is the best-known Danish funding agency for novel projects.

[Ed: EUDP supported another Aalborg CSP first; Denmark’s district heating plant Brønderslev Forsyning implemented the first CSP/biomass hybrid combined heat&power plant]