Solar Field – HTF – Power Block Commissioning

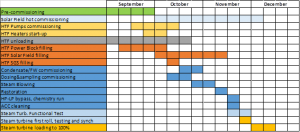

Since September to December 2020, commissioning of Urat Solar Field – HTF – Power block was performed, achieving 100% of steam turbine load while operating close to the winter solstice. The key factors to reach such a reduced schedule were the following:

- Engineering Phase:

- Basic Engineering review and coordination, adapting international EPC engineering practices to local engineering ones, in particular on normative and scope.

- Full Definition and DCS – SCS software development

- Solar Field

- Supply of Engineering and procedures. Supply of Jigs for Solar Field collector component Manufacture and Assembly, introducing new concepts from other designs that allow a higher assembly capability and easy traceability.

- By continuous QC / QA of the assembly process, up to each individual SCE, it was possible to identify when to carry out realignment of Jigs.

- Accurate initial balancing position definition, leading to fast reach of Solar Field outlet temperatures close to nominal.

- Solar Field logic improvement was helped by onsite engineering knowledge, as to troubleshoot on-the-go and analyse performance since initial focusing of SCAs.

- HTF System

- Operation of HTF systems on DCS during initial start-up of equipment and systems and on critical first-time operations

- Steamblowing definition and supervision by Ingenergio, coupled with SGS Engineering coordination, were key to optimizing the partial HTF filling while allowing the remaining SF commission to take place.

- Very high degree of Construction completion avoided halting commissioning activities due to lack of system finishing.

- High degree of piping cleanliness, both in SF headers and Power Block piping, resulted in no need for HTF pumps filter cleaning and unperceivable HTF boiling process.

- HTF sequential filling together with the afore mentioned cleanliness and fast HTF unloading, helped optimize the commissioning schedule, by eliminating the requirement of full plant HTF filling which is usually restrained by the HTF logistics.

- BOP System

- Overall coordination of commission activities on the water/steam cycle and auxiliaries

- Steam blow definition (Engineering): circuits, blow conditions, temporary tanks and piping, water programme… Blow supervision and target validation onsite.

- Definition of chemical control criteria during commissioning: dosing targets, sampling requirements, validation of on-line analysers, troubleshooting on excursions of iron, conductivity, silica…

- Overall coordination on transition from blows to turbine loading restoration, first steam, steam quality obtention, ST tests, plant operation during loading. Troubleshooting support for ST start-up limiters.

- TES System

- Coordination of Molten Salt Tank Engineering, including:

- Mechanical tank design

- foundations design

- instrumentation definition

- design review and validation of main equipment:

- Salt-HTF heat exchangers

- Salt pumps

- Electrical heat tracing

- Electrical tank heaters

- Detailed design of valves (HTF, salts, safety, and breather valves) and tank insulation

- Introduction of new suppliers to CSP application, leading to thorough review of equipment materials and functionality.

- Definition and validation of tank preheating equipment. Supervision of the preheating process

- Design of a high-capacity salts melting system, from conceptual to detailed equipment development.

Most relevant HTF-Solar Field Commissioning milestone schedule can be found below:

- Steam Blowing (main steam, reheat, bypasses) duration: 10 days.

- HTF expansion system injection peak of 570 tons per day, average of 200 tons per day.

- HTF loops filling, peak of 38 loops per day, average of 20 loops per day.

Apart from Engineering & Commissioning services, and acting as CSNP Tehcnical Advisor, Ingenergio has performed and is presently involved in other plant general tasks towards reliable and efficient plant life-cycle completion, as follows:

- Plant Maintenance general review, consultancy for organizing resources, spares and tasks on initial plant O&M

- Plant O&M procedures development,

- Overall SF-HTF-TES Engineering support during O&M:

- Performance evaluation

- Daily operation troubleshooting

- SF balancing tuning

- Optimization of SF operation: temperature control tuning, SF flow

- Adjustment of control&protection interlocks&settings, PB logic tuning

- Project Management advise on completion of EPC-like tasks for project completion:

- Plant punchlist follow-up, prioritizing tasks and allocating resources.

- Vendor contract completion

- Organizing Engineering As-Built documentation

- Plant overall performance test and environmental requirement completion