Beijing Jiajie new energy saving Technology Co., Ltd.( Jiajie new energy)—a “hidden champion” that has focused on molten-salt valves for eleven years—has officially become a member of the China Solar Thermal Alliance. With nearly 1,000 valve sets delivered, almost 500 units in stable operation, and several breakthroughs in domestic core technologies, the company now enters the industrial ecosystem as a key-component service provider. Guided by the principles of “innovation, efficiency, pragmatism and unity,” Jiajie new energy will help advance high-quality development of CSP and coal-plant flexibility retrofits.

Since entering the concentrating solar power (CSP) molten-salt valve segment in 2014, Jiajie new energy has pooled R&D resources from universities and research institutes, absorbed international best practices, and built a multidisciplinary technical team of thermal-control, electrical and valve engineers as well as O&M specialists, laying a solid talent foundation for technological breakthroughs.

Technically, the company was the first to localize the R&D and industrial application of core molten-salt-valve components, cutting costs by 60 % and shortening delivery time to 60 days. To solve chronic CSP pain points—large down-leg salt-pressure differentials, poor flow-control accuracy, difficult downstream pressure control, severe vibration and serious salt leakage—the team replaced conventional multi-cage trim with a recirculating counter-flow structure, eliminating cage plugging and control sticking. A flexible, self-compensating composite gasket between body and bonnet seals the perennial 320 °C–580 °C leakage. Eight such valves have already operated commercially in four CSP+ plants. Before the pandemic the company’s DN550 large-bore molten-salt valve set a domestic record and, with more than 200 units in service, became the standard for 1 GW-scale stations, saving a 100 MW tower plant nearly RMB 10 million in investment.

SDIC Aksai Huidong 110 MW CSP Project

SPIC Henan Company Xinjiang Shanshan 1 GW “PV + CSP” Integrated Project

Zhejiang Thermal Power Turpan 1 GW “CSP + PV” Integrated Project

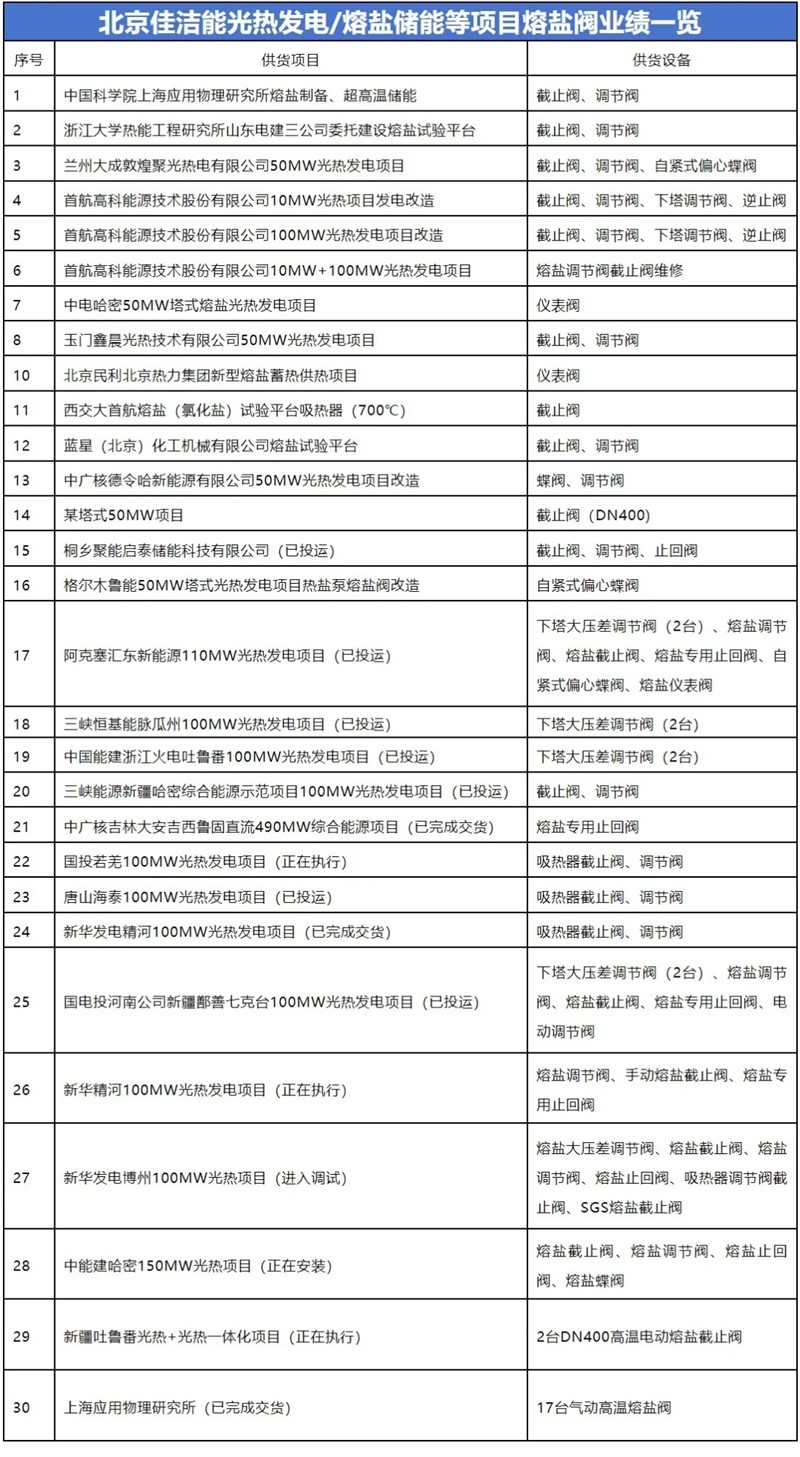

To date Jiajie new energy has shipped almost 1,000 valve sets to China’s first batch of CSP demonstrations, desert “CSP+” projects, molten-salt storage and coal-plant flexibility retrofits. In over ten benchmark plants—including SDIC Aksai Huidong 110 MW, SPIC Henan Shanshan 100 MW and Zhejiang Thermal Power Turpan 100 MW—nearly 500 units are running reliably, the earliest having logged more than 8,000 trouble-free hours. This reliability was proven during 45 months of rigorous testing on Zhejiang University’s 235 °C–565 °C thermal-cycling test rig and has won high praise from Shouhang High-Tech and Lanzhou Dacheng. Shouhang High-Tech stated the valves “can fully replace imported molten-salt valves,” and Lanzhou Dacheng’s 200-unit order for the Dunhuang 50 MW plant has performed excellently for years, a case featured by China Energy News.

Chairman Chen Jinhuang stresses that molten-salt valves must withstand frequent thermal cycling, violent temperature swings and diverse operating strategies. “Experience cannot be copied overnight nor replaced by pure technology; it is forged only through time and field proven practice,” he notes. Maintainability and part-interchangeability are equally critical: if a valve seat or plug cannot be repaired after salt freeze or erosion, the whole valve must be scrapped, whereas interchangeable spares can cut downtime from over a month to hours. Jiajie new energy therefore optimized structures and standardized core components from the design stage, lowering life-cycle O&M cost and system outage risk.

“At the same time, the maintainability and interchangeability of key molten-salt-valve components cannot be ignored,” Chen Jinhuang points out. “After a period of service, internal leakage is almost inevitable—whether from frozen-salt erosion or other causes. If the seat and plug cannot be repaired, the entire valve must be scrapped and a new one purchased. But if all parts of the same model are interchangeable, a spare can be swapped in within hours instead of weeks, cutting downtime dramatically.” A single valve failure, he notes, can idle the system for more than a month.

“Valve problems can delay commissioning by one or two months, and that is only the beginning. Performance issues and O&M costs during operation far outweigh any savings made at the tender stage; the money ‘saved’ will be repaid many times over,” Chen emphasizes. For this reason, Jiajieneng builds maintainability and interchangeability into the design phase—optimizing structures and standardizing core components—to lower life-cycle O&M costs and reduce outage risk from the outset.

On-site maintenance of a 24-inch molten-salt control valve from an international brand at an overseas project site

The product line covers all molten-salt valve types—high-pressure differential control, globe, check and butterfly—from DN15 to DN550, serving CSP collection, storage and heat-exchange sections as well as coal-plant flexibility retrofits. For northwest China’s extreme cold and salt-fog corrosion, the team can tailor material selection and structure, even undertaking special research topics. After commissioning in multiple tower plants in 2025, field-fit rate exceeds 98 % and stability is 15 % above industry average.

As molten-salt energy storage gains traction and flexibility retrofits multiply, Jiajie new energy invites power producers, EPCs and partners to join forces, using localized molten-salt valve technology to open new markets and help China reach its 2030 target of 15 GW CSP capacity with LCOE comparable to coal power.