On 21 September, the China Solar Thermal Alliance (CSTA) paid a visit to its board member Exera Energía(Exera)—Spain's leading CSP O&M service provider—in Seville. The mission was to draw on the 15-year track record of Gemasolar, the world's first commercial molten-salt tower plant, and to deepen China–Spain collaboration on high-performance, life-cycle operation and performance enhancement of CSP stations.

In the morning, the Chinese and Spanish sides focused on Exera's O&M technology for the 20 MW Gemasolar molten-salt tower CSP plant. Commissioned in 2011, Gemasolar is the world's first commercial molten-salt-tower plant and the first renewable facility to demonstrate round-the-clock power generation without sunshine, having set a record of 36 consecutive days of operation on solar energy alone.

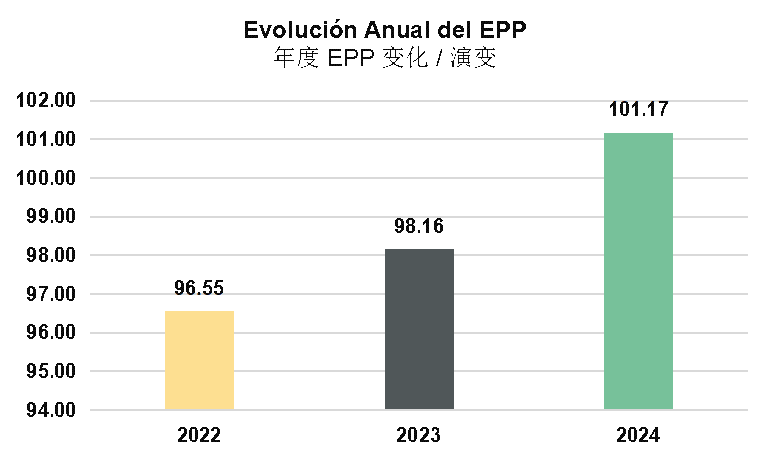

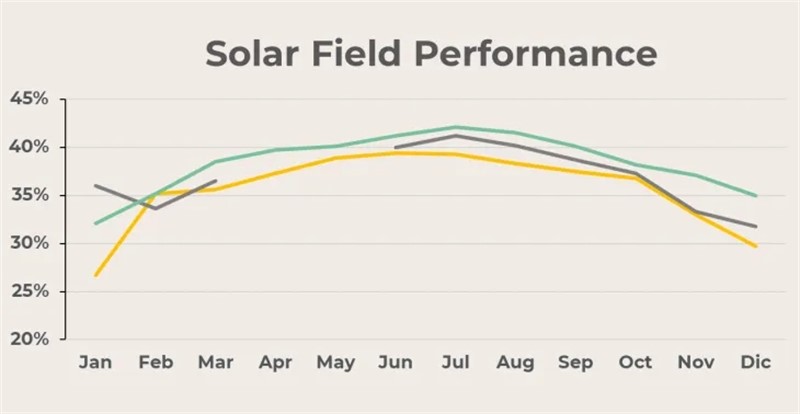

According to the company, Exera currently operates and maintains six CSP plants in Spain, and the stations under its management consistently deliver higher annual output than peer facilities under identical weather conditions. Drawing on more than a decade of hands-on CSP O&M experience—and the lessons learned from countless faults and events—Exera has developed a suite of digital tools: EOS, GymnOS, HerMES, DelfOS and TheIA. These platforms provide equipment-level data monitoring, predictive alarms and task-priority ranking, helping to raise generation and guaranteeing stable, reliable plant operation.

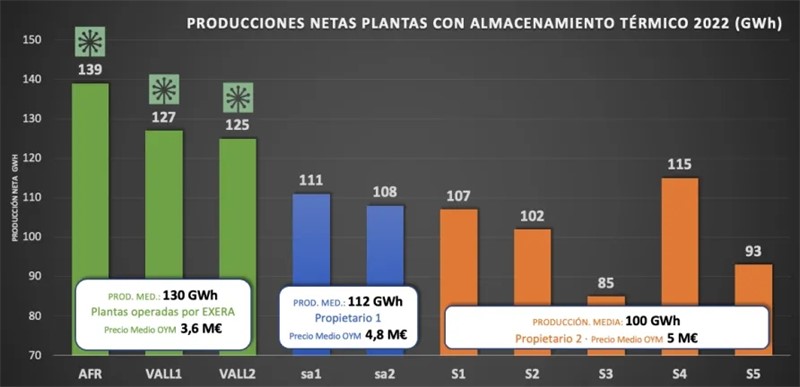

Chart note: the green bars on the left show the annual electricity generation of the three CSP plants operated by Exera—AFR, VALL1 and VALL2.

Exera stresses that a CSP plant's profitability and service life depend less on the hardware installed than on the quality of day-to-day management. A CSP station is far more than an assemblage of equipment and technology—its core lies in how it is managed. When management is both visionary and experienced, the plant’s earnings and longevity can be multiplied. To ensure CSP plants remain profitable and reliable over the long term, Exera offers four key recommendations:

1. Predictive O&M

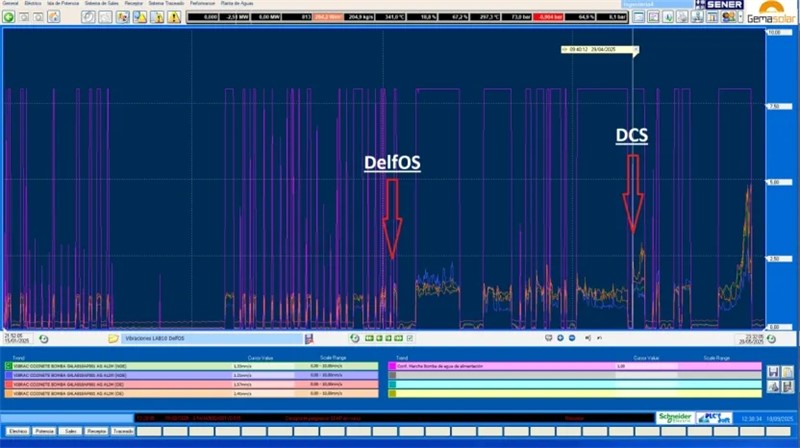

In the early years of operation, corrective repairs often arrived without warning, forcing CSP operators into a purely reactive stance. A decade of experience, however, has enabled Exera to build a systematic inspection regime, precision preventive-maintenance schedules and predictive-analytics techniques that detect and resolve issues before they surface. This shift is pivotal: plant availability rises and O&M costs stabilise. Exera has now pushed the forward-looking philosophy to a new level through prescriptive-maintenance tools that not only forecast when a component might fail, but also specify exactly what action to take—and when—to prevent the fault from ever affecting generation.

Chart note: Using its in-house DelfOS O&M tool, Exera detected an anomaly in a cooling-tower fan blade and carried out a proactive intervention, eliminating a corrective repair that would likely have been required within the next few months and preventing 145 MWh of lost generation.

Chart note: In the feed-water pump three-way valve case, Exera pinpointed the fault by analysing both the averaged KPI trend from multiple vibration sensors and the instantaneous KPI generated by its algorithm. The DCS screen capture shows that the abnormal pattern was not flagged until 29 April 2025, whereas the DelfOS platform had already issued an alert 1 month and 10 days earlier. This head-room determined whether the incident would be resolved through a minor intervention, a major overhaul, or a catastrophic failure.

Chart note: An early warning from DelfOS on a feed-water pump three-way valve averted 311 MWh of lost generation, eliminating the corrective maintenance—and associated summer-peaking output loss—that would otherwise have occurred in the following months.

Chart note: DelfOS detected the detachment of insulation at the bottom of the LP turbine casing, preventing 308 MWh of lost output by eliminating a potential unit-start delay that would have depressed the entire plant’s generation.

2. Digital empowerment

The greatest leap in Gemasolar's history was the move from a reactive, operator-experience-driven model—where plant performance hinged on basic SCADA alarms and individual skill—to a proactive, prevention-first regime. Digitalisation led the way, followed by the integration of artificial intelligence. Exera has built a full digital twin of the plant that replicates operating scenarios and delivers real-time predictive analytics. Coupled with simulation engines, forecasting tools and an advanced monitoring dashboard, the twin gives millimetre-accurate insight into every component, shifting management from “what is happening now” to “what will happen next.” This data-, trend- and prediction-centric approach is the key to safer, more efficient and more profitable operation.

3. Early-team involvement & continuous training

Experience shows that a well-trained O&M team can outweigh the advantages of the hardware itself. Exera stresses that embedding the O&M crew during the final construction phase is critical: team members witness every installation step and take part in the full commissioning and start-up sequence. Coupled with regular training modules, this approach gives the team both the theoretical understanding of every component and process and the hands-on know-how of system tuning, inspection and maintenance.

4. Extreme-event playbooks

Owners and operators must focus on resilience—the plant's ability to withstand, adapt to and recover from sudden shocks. Spanish CSP plants have endured extreme heat that tests material limits, storms that batter heliostat fields, molten-salt spills and other emergencies. Whether a site emerges stronger from these events hinges on the depth of preparation put in place beforehand. Clear procedures, regular drills, strategic stocks of critical spares and a meticulously designed emergency plan make the difference when crisis strikes.

Exera has long specialized in this field, crafting tailor-made resilience plans for each plant. These plans go beyond technical measures to include organizational coordination: how teams collaborate during an emergency, how they communicate with grid dispatchers, and which actions take priority in the first critical minutes.

“Predictive mindset, digital tools, continuous training and extreme-event preparedness are not abstract slogans,” Exera says. “They are concrete instruments. Used well, they draw the line between a fragile plant and one that is resilient, reliable and profitable. Investing in these four areas is an investment in the plant's future—and, ultimately, in the success of the energy transition.”

In the afternoon, the Chinese CSP delegation visited the Gemasolar molten-salt tower plant operated by Exera and held an in-depth discussion in the control room. The facility—the first commercial molten-salt tower CSP plant ever built—is regarded as a milestone in solar-thermal history. Equipped with 15 hours of thermal storage, Gemasolar can generate electricity through the night or during sunless periods, smoothing renewable intermittency and delivering near-baseload power.

On future China–Spain collaboration, Exera points out that Chinese CSP plants resemble their Spanish counterparts in some respects, yet also face distinct differences. China's climate, regulatory framework and grid behaviour all introduce non-negligible variables. After two years of field research, however, Exera concludes that many of the solutions it has developed in Spain are fully transferable to the Chinese context, including:

- Proven molten-salt, receiver-control and life-cycle procedures

- Digital O&M platforms for fault prediction and performance optimisation

- Bespoke training curricula adapted to local conditions

- Resilience plans for extreme-event continuity

Wang Zhifeng, Professor of the Institute of Electrical Engineering at the Chinese Academy of Sciences and Chairman of both the CSTA and the Solar Thermal Power Committee of Chinese Renewable Energy Society remarked:

“Gemasolar opened the commercial era of molten-salt tower CSP; it is the benchmark project. Fault early-warning, diagnostics and O&M technologies are the keys to unlocking CSP's full potential. Through this in-depth exchange and site visit we have seen Exera's capabilities and its dedicated tools. The cooperation potential between China and Spain in solar-thermal power is enormous. This visit was not merely a technical inspection—it was a successful prologue to international collaboration. We are confident that, by drawing on global experience, China's CSP industry will steadily move toward ever more economical electricity generation.”

The delegation also included:

- Wang Yisheng, Vice-Chairman of the China Chamber of Commerce to the EU

- Exera executives: CEO Alfredo Valenciano, China General Manager Enrique García, CTO Juan Manuel Medel, O&M Director Raúl Mendoza, and Chief Digital Officer/Software Architect Manuel Vázquez

- Sebastián Fernández, Plant Manager of Gemasolar

- Exera China business representatives: Shan Shipeng and Lin Chenyi

- Dr. Manuel Romero, former Deputy Director of IMDEA Energy

- Dr. Wang Ye, researcher at the Australian National University

- Du Fengli, Secretary-General of the CSTA

as well as representatives from CSTA board member organizations:

ROYALTECH ,

Hubei Yuntu Molten Salt Technology Co., Ltd.,

Institute of Electrical Engineering, Chinese Academy of Sciences, and

Cosin Solar Technology Co., Ltd.