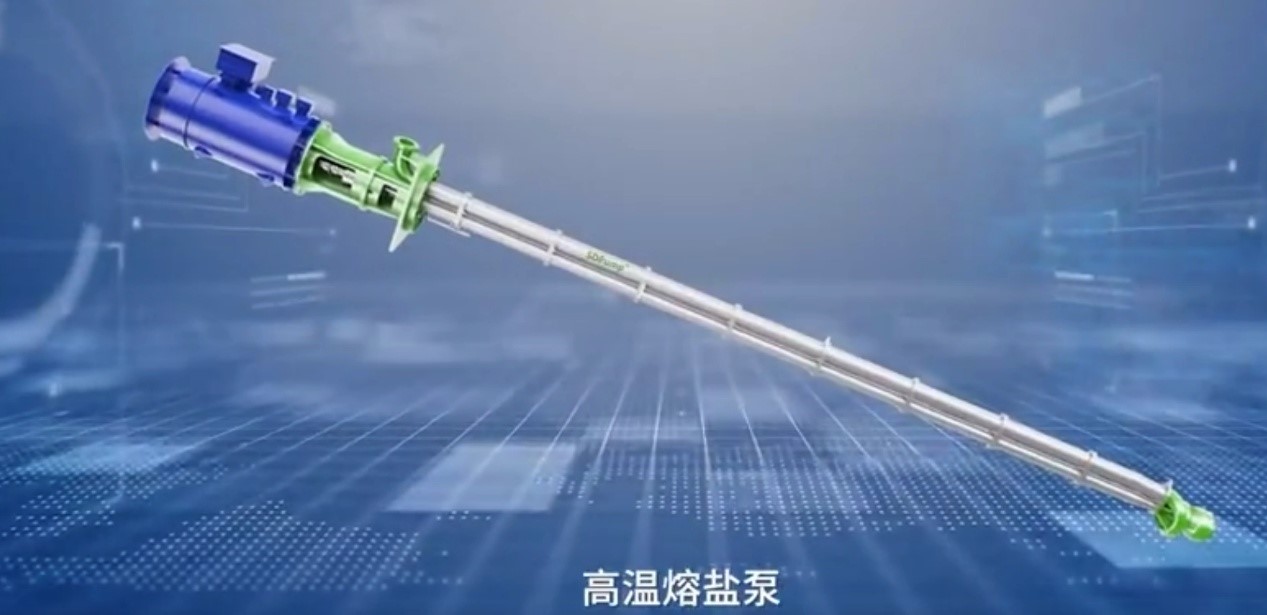

10 July 2025: The RY(L) series high-temperature molten-salt pump independently developed by Jiangsu Shuangda Pump Industry Co., Ltd. (hereinafter “SDPump”) has passed the appraisal of the China General Machinery Industry Association. The pump was judged to have “core technical indicators on par with the advanced level of comparable domestic products,” signalling that domestically produced molten-salt pumps will become a new growth engine for SDPump. The company has now been officially approved as a governing-board member of the CSTA after a joint meeting vote.

In SDPump’s workshop test area, a 16-metre-tall RY(L) pump is undergoing simulated trials. Engineers monitor vibration, noise, flow and other parameters in real time through a test bench that replicates the actual operating environment of a solar-thermal power plant, ensuring every unit is rigorously validated before shipment. According to the R&D department, SDPump began developing the pump in 2016, achieving breakthroughs in materials, structure and suction hydraulics. The pump can transport media at up to 600 °C and is positioned as a drop-in replacement for imported units. It has already been granted several national invention patents. Notably, after years of field experience, targeted R&D and iterative optimisation in the CSP sector, SDPump now professionally designs and manufactures CSP-specific high-temperature molten-salt pumps (cold-salt, hot-salt and temperature-regulating pumps), boiler feed pumps and high-temperature hot-water pumps. The newly certified RY(L) series has entered mass production with a healthy order backlog.

SDPump is primarily engaged in the production and sale of petrochemical pumps, slag crushers and composite pipelines. In recent years the company has focused on mid- to high-end products, specialising in the R&D, manufacture and sale of large, critical petrochemical pumps for refining, new coal-chemical, new-energy and advanced-material applications. Its corrosion-resistant and chemical process pumps enjoy a strong reputation in petroleum refining, chemicals and non-ferrous metallurgy. The company serves nearly 1,000 long-term customers, including CNPC, Sinopec, CNOOC, China Shenhua and China National Chemical Engineering.

As a high-tech enterprise and AAA-rated quality-reputation firm, SDPump is a specialised manufacturer of both petrochemical pumps and composite pipelines. Guided by the principles that “innovation is the source, development is the root, talent is the foundation and integrity is the way,” the company polishes the “golden signboard of Jingjiang manufacturing” with craftsmanship.

Located in the Xinqiao Industrial Park of Jingjiang Economic Development Zone, Taizhou, Jiangsu Province, SDPump enjoys excellent logistics advantages and close collaboration with nearby suppliers and customers.

In R&D, SDPump operates a provincial-level enterprise technology centre staffed by more than 60 specialised engineers. The company invests over RMB 20 million annually in R&D and launches more than three new products each year through long-term university–institute partnerships. Joint projects with Jiangsu University and Lanzhou University of Technology have enabled continuous upgrades from single-stage to ultra-high-speed multistage centrifugal pumps; a collaboration with Shanghai Jiao Tong University targets deep-sea oil & gas transfer pumps to overcome “choke-point” technologies and develop internationally competitive offshore equipment. To date, SDPump holds 92 patents and has established joint laboratories with Shanghai Jiao Tong University and the Institute of Engineering Thermophysics of the Chinese Academy of Sciences, creating a complete technical chain from materials R&D to system integration.

On the manufacturing side, SDPump is equipped with state-of-the-art facilities capable of producing 5,000 industrial pumps, 12,000 tonnes of composite piping and 1,000 tonnes of metal castings per year. Lean and just-in-time production principles allow “tailor-made, zero-inventory” operations.

Looking ahead, SDPump will further enhance its R&D strength and market competitiveness, accelerate industrial upgrading and realise higher-quality development.