Background: In the second half of 2024, Qinghai Province initiated the selection process for its "CSP Demonstration (Pilot) Project." This initiative aims to fully leverage the advantages of solar thermal power generation, such as its flexibility, grid-friendliness, and dispatchability, to promote its large-scale and independent development vigorously. The three selected projects will receive a feed-in tariff of 0.55 RMB/kWh. Each project has a capacity of 350 MW and is equipped with a long-duration molten salt thermal energy storage system. These demonstration projects will fully utilize the capabilities of solar thermal power generation for peak regulation, frequency regulation, etc., contributing to the stable and efficient operation of Qinghai's energy and power supply. Furthermore, the implementation of these projects will lay a solid foundation for the large-scale, low-cost, and intelligent development of solar thermal power generation technology in China.

Cosin Solar's awarded Qinghai Yichu Golmud 350MW Tower CSP Project (the ‘Project’) is the world's largest single-unit solar thermal power project in terms of installed capacity, heliostat field reflective area, energy storage scale, and designed annual power generation.

The project will utilize Cosin Solar's entirely self-developed core molten salt tower CSP technology. Cosin Solar will be responsible for the whole process management of the project, including project management, overall plant process design (excluding Power Block), supply of core system equipment, commissioning, operation & maintenance (O&M), and other technical services.

Cosin Solar began research on system solutions and related core technologies and processes for a 350MW-class CSP project as early as 2022. By July 2024, the company had independently completed the design of the plant system solution. It successfully developed Concentrating Solar Collector System and Molten Salt Thermal Storage & Exchange System process packages suitable for a 350MW-class CSP project, reaching basic design depth. This provides a solid technical guarantee for the smooth implementation of the project. Subsequently, the design institute will carry out engineering design based on this foundation.

Currently, the project has completed the feasibility study report preparation and review, as well as the bidding and final selection for engineering design. Civil construction and main equipment bidding are underway. Construction is officially planned to commence in September this year.

Unit Capacity Leaps to 350MW Class with Multiple Major Technological Innovations

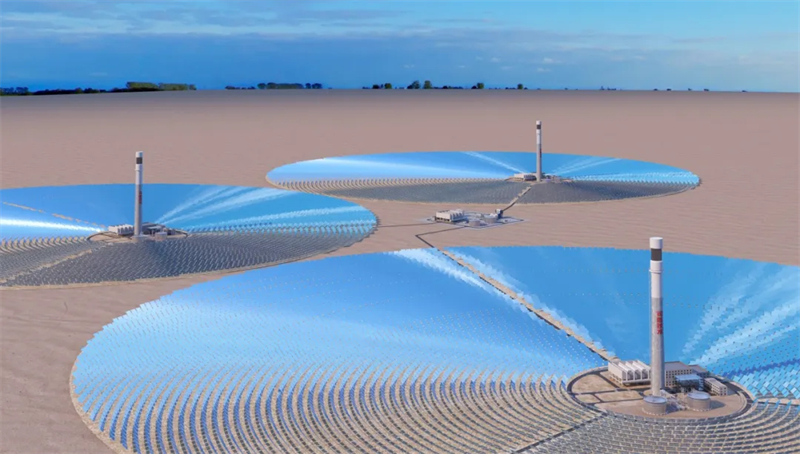

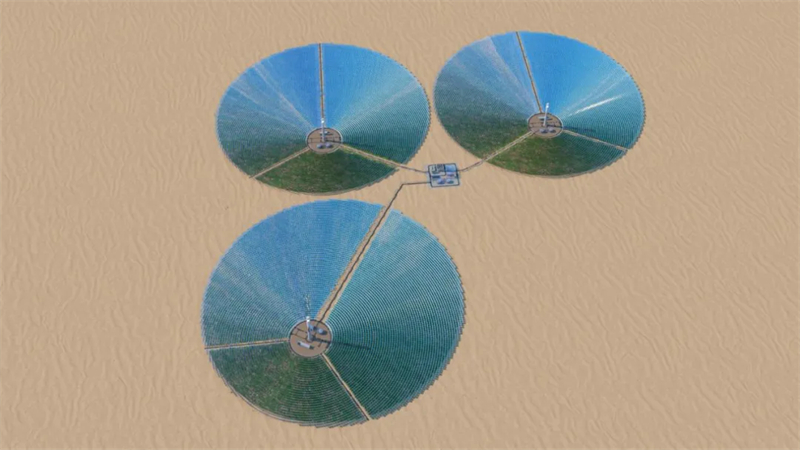

The project adopts a "three-tower-one-unit" design scheme, configured with a 14-hour molten salt energy storage system. The total reflective area of the heliostat field is 3.3 million square meters. Facing the technical challenges of ultra-large-scale concentrating solar collector systems and Molten Salt Thermal Storage & Exchange System, Cosin Solar has innovatively developed multiple core Tower CSP technologies:

Ultra-Large-Scale, Intelligent Concentrating Solar Collector System

The Project's heliostat field control scale reaches 89,000 heliostats. It will utilize Cosin Solar's self-developed high-precision, intelligent concentrating solar collector system, including 37m² high-precision intelligent heliostats, ultra-large-scale heliostat field cluster control technology, multi-field energy coordination control technology, and high-capacity, safe, and efficient molten salt receiver technology.

a. Heliostat and Field Control System Technology Upgrade

The scale of the Project's heliostat field imposes higher requirements on heliostat surface shape accuracy and tracking precision. Cosin Solar's self-developed high-precision surface shape control technology, combined with a machine vision-based unattended fully automatic heliostat calibration system, enhances the tracking accuracy of the new-generation 37m² heliostat, effectively ensuring the concentrating efficiency of the Project's heliostat field. Additionally, this heliostat product exhibits excellent wind resistance, with maximum operating wind speed and survival wind speed further improved. Simultaneously, Cosin Solar has further optimized large-scale distributed communication networks and cluster control technologies, enabling intelligent detection, diagnosis, management, and real-time control of the entire heliostat field, meeting the needs of gigawatt-scale peak-shaving solar thermal units.

b. High-Capacity, Safe, and Efficient Molten Salt Receiver Technology

To address challenges such as long receiver preheating times under high wind speeds, Cosin Solar has developed an optimized molten salt piping design for the receiver system, a receiver header sealing technology adaptable to strong winds and ultra-low ambient temperatures, and an integrated insulation solution. These innovations ensure the safe and efficient operation of the receiver under extreme environmental conditions.

High-Reliability, Distributed Multi-Tank Molten Salt Thermal Energy Storage System

The Project's thermal storage capacity reaches 10.6 GWh, utilizing four sets of molten salt storage tanks with a total designed molten salt volume of 107,000 tons. Given the massive energy storage scale, high system complexity, and extremely high reliability requirements, Cosin Solar has developed a complete Molten Salt Thermal Storage & Exchange System process package and innovatively proposed a distributed molten salt energy storage system solution and a unique low-position tank short-shaft pump technical solution.

a. Distributed Molten Salt Energy Storage System Solution

Cosin Solar has developed a distributed molten salt energy storage system solution for a large-capacity multi-tower-single-unit Tower CSP plant. This solution involves dispersing the molten salt thermal storage systems near the center of each heliostat field and the power block. This elegantly solves problems associated with long-distance molten salt transport, such as slow system response and long start-up/shutdown times. It also optimizes the Molten Salt Thermal Storage & Exchange System configuration and transport scheme for the multi-tower-single-unit design based on the operational characteristics of peak-shaving solar thermal plants, significantly reducing the investment cost for long-distance molten salt pipelines. This technology has been applied for national and international patents.

Advantages:

ü Eliminates the delay impact of long-distance molten salt transport on receiver system start-up, enhancing operational flexibility.

ü Optimizes Molten Salt Thermal Storage & Exchange System configuration, enabling more flexible energy dispatch and improving system resilience.

ü Through optimization of long-distance molten salt pipelines, the comprehensive cost of the thermal storage system can be reduced by approximately 10%.

b. Low-Position Tank Short-Shaft Pump Technical Solution

To enhance the operational reliability and cost-effectiveness of the Molten Salt Thermal Storage & Exchange System, Cosin Solar has innovatively developed the low-position tank short-shaft pump solution. By shortening the molten salt pump shaft length, the reliability of the molten salt pump is increased, and O&M costs are reduced. Simultaneously, it reduces the proportion of unusable molten salt (‘dead salt’), decreasing the steel usage for tanks and the total molten salt volume required. This technology has been granted patents in China and several other countries and has been successfully applied at the Jinta Zhongguang 100MW Tower CSP Project.

Advantages:

ü Reduces the design and manufacturing difficulty of molten salt pumps by shortening the shaft length. It fundamentally addresses the challenges of long-shaft molten salt pumps, such as high foundation platform requirements and susceptibility to vibration, improving pump reliability and maintenance convenience.

ü Effectively solves the ‘dead salt level’ issue in conventional solutions. The minimum tank liquid level is reduced from around 1 meter to below 0.5 meters. This significantly reduces molten salt usage and tank steel consumption while achieving the same energy storage capacity.

ü Using this solution, the comprehensive cost of the thermal storage system can be reduced by up to 12% compared to conventional schemes.

Highly Intelligent CSP Plant Smart Operation System

CSP plants face challenges such as complex operational processes, numerous pieces of equipment, high operational difficulty, insufficient professional talent, low intelligence levels, and difficulties in operational performance assessment. The operational practice of the first batch of CSP demonstration projects shows that, limited by low plant automation and high dependence on operator skills, power generation achievement rates vary significantly, and performance improvements for most projects are slow. Leveraging the successful operational experience of the Qinghai SUPCON SOLAR Delingha 50MW Tower CSP Project and deep expertise in Tower CSP plant design, process, equipment, and operation technologies, Cosin Solar has developed a series of innovative solutions to address these pain points:

a. CSP Plant Simulation Training Platform

Cosin Solar's self-developed simulation training platform offers comprehensive plant equipment simulation and operator training functions, providing full support for training O&M personnel for solar thermal power plants. It consists of a simulation model system, trainee station software, and instructor station software.

ü Precise Modeling & Simulation: Enables free system construction via visual drag-and-drop. Quickly converts system design schemes into simulation systems. Supports functions like weather simulation and infrared temperature measurement data simulation, achieving full-condition simulation of CSP plants.

ü Immersive Operation Training: The trainee station software uses the actual control interface to simulate daily operations and various scenarios of abnormal weather and equipment faults. Helps operators familiarize themselves with operating procedures and emergency plans, rapidly improving operational and fault response capabilities.

ü Intelligent Training Management: The instructor station software controls progress and monitors data in real-time. The system automatically records and analyzes trainees' operation records, generating quantitative assessment reports based on multiple dimensions such as compliance with operating specifications, response speed, and handling effectiveness. This enables precise assessment and guidance for improvement.

b. Intelligent Operation System for Concentrating Solar Collector System

To address difficulties like high cloud cover proportions at domestic solar thermal plant sites, complex operating conditions, and high operational difficulty, Cosin Solar has independently developed an Intelligent Operation System for the Concentrating Solar Collector System. This system can accurately identify weather changes and automatically switch operating modes, enabling one-click start-up, one-click heat collection, and one-click salt drainage for the Concentrating Solar Collector System. The system integrates multi-modal data to establish a real-time operational model of the Concentrating Solar Collector System. It intelligently identifies local cloud shading conditions and employs an automatic field energy coordination control strategy to achieve refined energy dispatch under cloudy conditions, reducing energy dumping and maximizing heliostat field energy utilization. The application of this system significantly reduces plant operation difficulty, improves system operational reliability, and increases collected thermal energy.

C. Smart Management Platform for CSP Plant Operation

Cosin Solar has newly developed a cloud service-based Smart Management Platform for CSP Plant Operation. Through a digital-intelligent management platform, scientific data analysis platform, and intelligent supervision platform, it comprehensively addresses the difficulties in optimizing CSP plant operations, providing strong support for users at different levels:

ü Enhance Production Efficiency: Provides a digital-intelligent management platform integrating functions such as daily operation report management, equipment intelligent diagnostics, weather forecasting & disaster warning, power prediction, etc., continuously improving plant management efficiency.

ü Guide Operational Optimization: Provides an operational analysis platform, including automatic statistical analysis of operational data and intelligent analysis of plant performance deviation causes. This offers an effective tool for continuously optimizing plant efficiency and maximizing revenue.

ü Enhance Owner’s Supervision: Provides an intelligent supervision platform, including local and remote smart monitoring dashboards. This helps owner enterprise groups quickly gain insights into frontline production status, optimize decision-making processes, and enhance management efficiency.

As the power system rapidly advances towards marketization, achieving breakthrough development in the solar thermal power generation industry necessitates low cost and large scale. As the world's largest single-unit solar thermal power project, the Qinghai 350MW Independent CSP Project will accumulate crucial experience in technology, equipment, engineering, and operation. It will provide a comprehensive demonstration of the development of the CSP industry in China and globally. Leveraging its deep expertise in the CSP field, Cosin Solar has fully mastered the core capabilities for the design, construction, and O&M of large-capacity CSP projects, achieving innovation in key technologies and systems. Committed to the successful implementation of the Qinghai 350MW CSP Project, Cosin Solar aims to accelerate the industry's large-scale development and rapid cost reduction, propelling it towards a new stage of high-quality development.