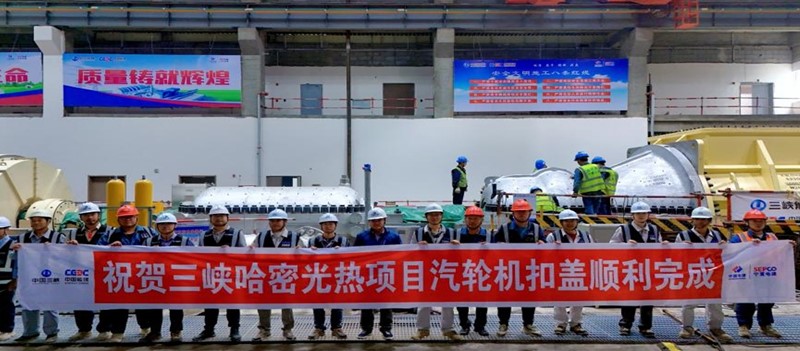

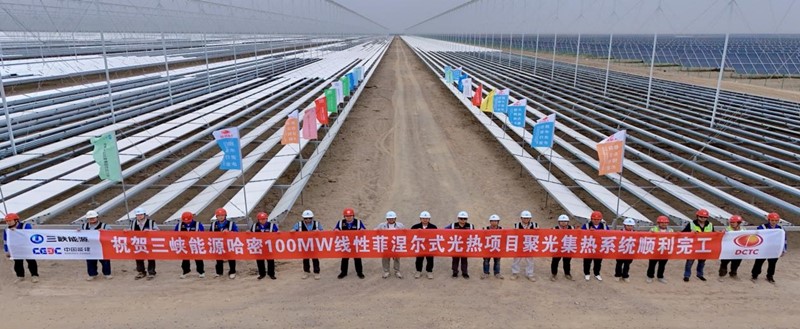

On May 20th, the CTGR Hami 100MW Linear Fresnel CSP Project in Xinjiang welcomed two key milestones—the successful casing closure of the turbine and the completion of the concentrated heat collection system. This marks the project's entry into the final sprint towards commissioning.

The project is contracted by Northwest Electric Power Design Institute Co., LTD, of China Power Engineering Consulting Group, a vice chairman unit of the CSTA. The concentrated heat collection system is undertaken by Dunhuang Dacheng Energy New Energy Technology Co., Ltd., a subsidiary of Dacheng Technology Co., Ltd., which is also a vice chairman unit of the Alliance.

Considering the characteristics of solar thermal unit operation, Northwest Electric Power Design Institute Co., LTD, of China Power Engineering Consulting Group has focused on adapting to frequent and rapid start-stop operations in the unit design concept, ensuring safe and stable operation while enhancing economic performance across a wider load range. The turbine employs high-efficiency wide-load blades, effectively addressing the industry-wide issue of significant efficiency drops during low-load and variable operating conditions. Additionally, the optimization of the last-stage blade flow field reduces losses in the low-load area, enabling better adaptation to the complex operating conditions of solar thermal power.

After ten months of arduous efforts, the CTGR Hami project team from Dunhuang Dacheng Energy overcame adverse conditions such as extreme heat, cold, sandstorms, and snowfall. They adhered to high standards and strict requirements, focused on project quality, and creatively carried out construction work. They worked hard to meet deadlines while prioritizing safety, ensuring the successful completion of all construction tasks.

The CTGR Hami 100MW Molten Salt Linear Fresnel Solar Thermal Power Generation Project features a concentrated heat collection system covering an area of 802,600 square meters and is equipped with 8 hours of heat storage. It is invested and constructed by CTGR New Energy Hami Wind Power Co., Ltd. Multiple council units of the Alliance participated in the construction. China Energy Engineering Group Central. China Electric Power Test and Research Institute Co., Ltd. was awarded the joint design and construction general contracting. Xi'zi Clean Energy Equipment Manufacturing Co., Ltd. supplied the steam generator. Hangzhou Huayuan Frontline Energy Equipment Co., Ltd. provided the heating station. Shanghai Feiting Pipe Manufacturing Co., Ltd. won the bid for molten salt pipeline materials, fittings, and factory procurement. Jiangsu Feiyue Pump Co., Ltd. was awarded the contract for domestic cold salt pumps and salt discharge pumps. Shanghai Yanao Valve Co., Ltd. won the bid for molten salt medium instrument valves. Shanghai Lanbin Petrochemical Equipment Co., Ltd. was awarded the contract for molten salt storage tanks (systems and equipment).