Pioneering the Seas: Xavier Lara at AELIUS Energies to champion sustainable shipping with green ammonia before the world’s largest shipbuilding industry.

Converting global shipping to run on green ammonia instead of heavy fuel oil is an idea whose time has come, according to the CEO of the international energy consultancy AELIUS Energies SLU.

CEO Xavier Lara will fly to China at the end of June to sell the concept of green ammonia for sustainable shipping to the largest shipbuilding industry in the world and, hopefully, to arrange the first trial.

AELIUS Green ammonia

Lara will present the case for converting shipping to green ammonia at the 2023 East Asia Cooperation Platform’s Qingdao Forum at the “Harmonious Coexistence in the Ocean Decade” event held on June 27-29th in Qingdao City, organized by China’s Ministry of Natural Resources and the Shandong Provincial Government. His presentation is “Navigating Towards a Greener Future; Green Ammonia and Retrofitting of Two-Stroke Engines in Maritime Transportation. This event is part of the UN’s Decade of the Ocean agenda, and Xavier will present it in front of heads of UN Agencies, ASEAN plus Three (APT), marine-related international organizations and senior marine officials.

How serious is the world’s largest shipping industry about moving to a sustainable shipping future?

“China is covering all the expenses for this trip, which in my view, signals a strong interest in the initiative,” he said in a call from Spain.

“The Ministry of Natural Resources of China has invested in bringing us there for this presentation. This leads me to believe that they are considering a practical trial, as their investment suggest a commitment to exploring the potential of green ammonia for shipping”

Attendees include China Shipbuilding Industrial Corporation. A division of this state-owned firm; CSNP was involved in an innovative pilot Concentrating Solar Power (CSP) plant in China that tested an award-winning silicon-based higher-temperature heat transfer fluid for the first time in a commercial 100 MW CSP project, The Urat CSP project has gone on to break records in night generation. Interestingly, it was Lara who sold the basic engineering of this project to CSNP and participated in several meetings in Beijing during the engineering phase, reviewing it.

Having personally experienced this willingness to test green tech innovations at full scale, he believes that it bodes well that China could well pioneer this approach to sustainable shipping.

AELIUS Energies on ship conversion to green ammonia

Future: green ammonia with solar thermochemistry

Because green ammonia is a potential drop-in solar fuel to power the heavy shipping industry, it has been a solar thermochemistry research topic, with Australian researchers advocating for it to be used as a safer, cheaper carrier to deliver hydrogen as “a better hydrogen carrier than hydrogen.”

US researchers are developing specialized solar reactors to produce green ammonia, (NH3) which is made up of hydrogen and nitrogen. Extracting hydrogen from water is already a well-demonstrated solar thermal process (as a step in making solar aviation fuel commercially), and now, finding the most efficient cycle for separating nitrogen from the air is a current solar thermochemical research topic.

Lara’s background includes work on almost all the major international CSP projects, and he expects solar thermochemistry to play a future role in making green hydrogen due to the thermal efficiency of solar heat used directly.

As an example, he points to China’s focus on the bottom line:

“Here is a country manufacturing most of the batteries in the world. So then the question is, why is the country that manufactures the most batteries in the world also the only country in the world to require at least 10% of the capacity in every renewable energy park to be CSP with its thermal storage? Why? Because it is lower in levelized cost of storage (LCoS) with its molten salts storage than equivalent PV+batteries. So China is mandating CSP inclusion because of the numbers.”

As a long-time champion of CSP, he interjected the hope that other Sunbelt regions such as the southwest US states should understand this storage advantage that China has acted on. “CSP with its storage is the ideal solution to California’s duck-curve, and it can be built in US with a 100% American supply chain at a better LCoS than BESS,” he said.

However, the solar thermochemistry route to green ammonia, though promising, is not yet at commercial readiness, unlike electrolysis. So Lara is building on the recent announcements of two major electrolysis projects in the EU to generate green hydrogen to supply ammonia for shipping.

Ships can be converted to run on green ammonia, as well as to carry it as cargo

Bird in the hand

With these two large, well-funded electrolysis manufacturing deals already underway in Europe, the first green ammonia will soon be market-ready. Lara is more concerned with first creating an initial market for green ammonia in the shipping industry before it is too late from a climate point of view. His focus is on converting the shipping industry the fastest way possible, which is why he is going to China.

“China now probably has the biggest shipping fleet in the world, it is bigger than the US now, and they are looking to decarbonize it,” he commented.

“They have a huge shipyard industry. You know they are already experts in manufacturing, with robotics. They are approaching this not only from the point of view of the money but as something strategic because it gives them independence from oil in the transportation market. Green ammonia is a very attractive strategic fuel because every country can generate it. This is an approach that I think US should replicate in their shipping industry also.”

He hopes to sign an MOU with a consultancy contract to help the first ship to pioneer this sustainable shipping conversion “because it’s one thing to have a theoretical case to read – but the faster step is to have a case in practice.”

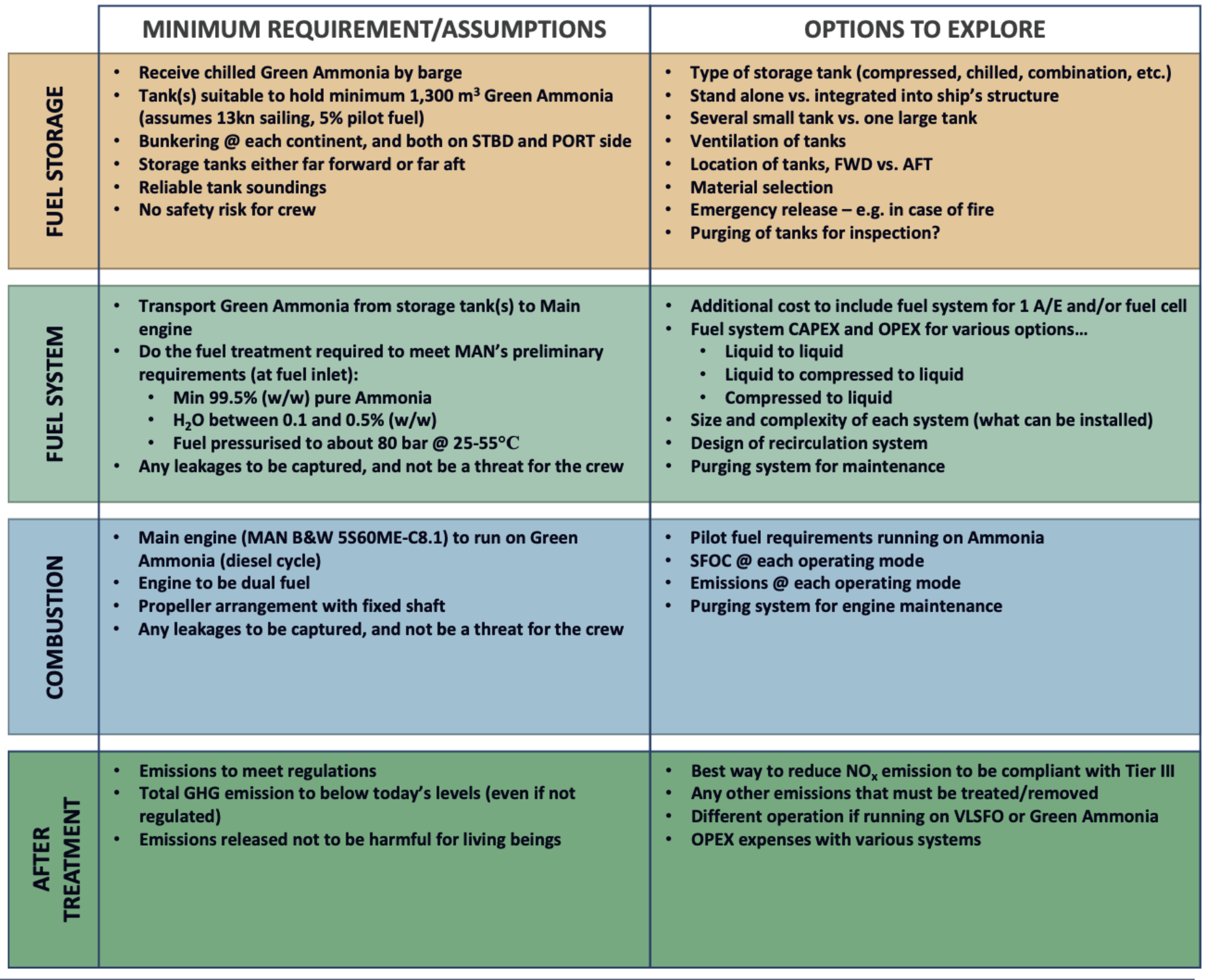

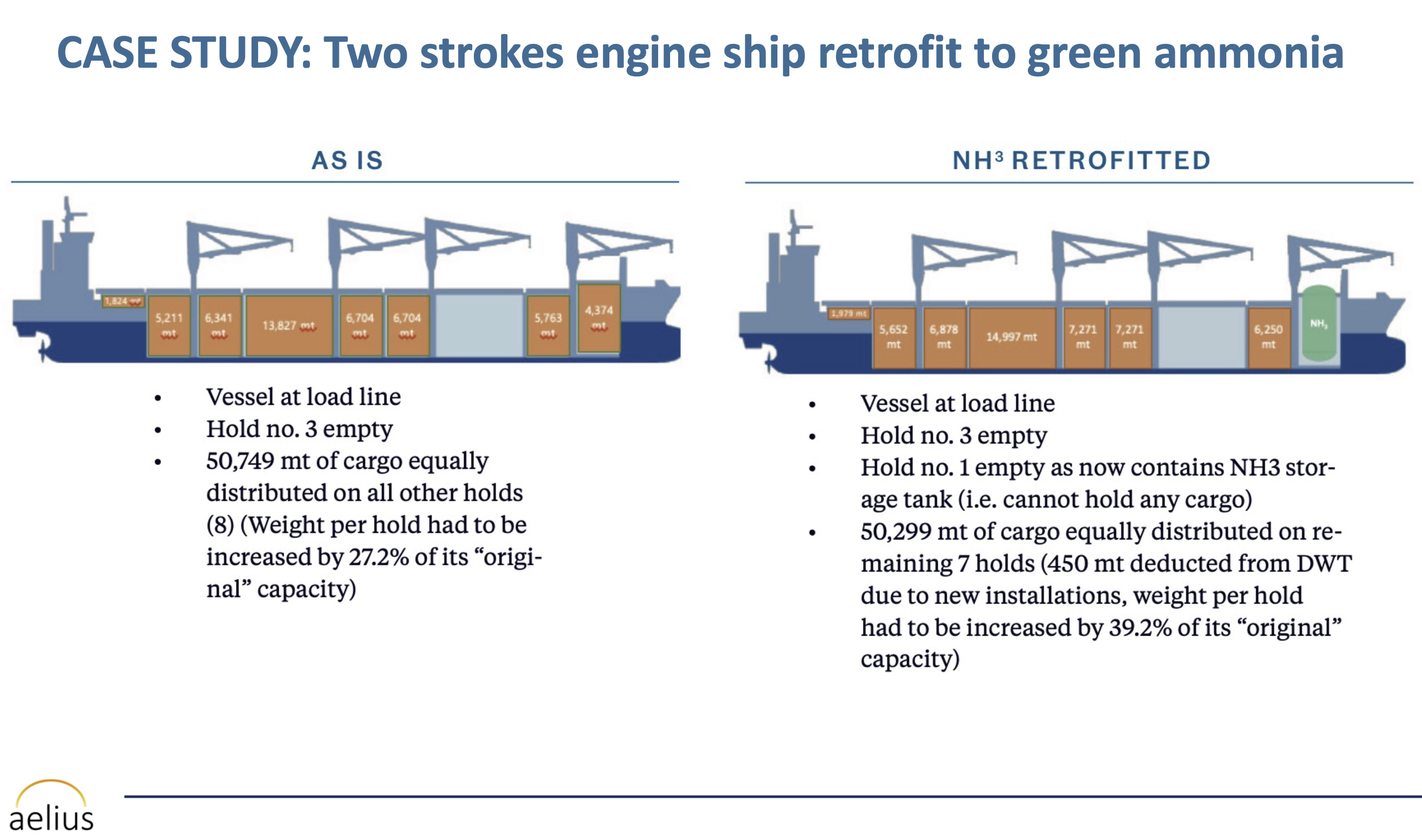

Converting big ships to run on ammonia fuel will be a big ask, and the cost will vary depending on which technology they currently use.

“The conversion is about $22 million,” he explained.“The fuel that these ships burn now is heavy fuel in a diesel engine. These engines can burn nearly anything, even Jack Daniels Whiskey! If the ship has a gas turbine, you can also do conversions, but these are different. We focus a lot on these because most ships have these big reciprocating engines, and it’s a very straightforward conversion to burn ammonia.”

Despite the cost of the one-time investment, over time, as carbon taxes rise, he believes it will have been cheaper to convert these big ships.

“With the European Union carbon Tax, the ETS, we know that at some moment, it will not simply be a fuel cost,” he pointed out. “The emissions will be taxed so high that if you’re burning oil, it will no longer be competitive. The business case is even here already, as we will show in our presentation in Qingdao.”