Solar-thermal power can replace fossil fuels in a wide variety of industrial applications, including petroleum refining, chemical production, iron and steel, cement, and the food and beverage industries, which account for 15% of the U.S. the economy’s total carbon dioxide (CO2) emissions.

Heat is vital to the production of almost everything we use on a daily basis: from cosmetics and textiles to steel and computer chips. In the United States, fossil fuels generated 90%

of reported manufacturing process heat energy in 2014, which is a big reason why the industrial sector accounts for approximately one third of the nation’s energy-related CO2 emissions.

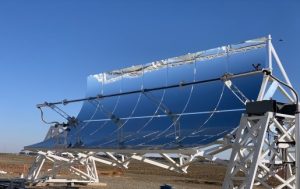

Concentrating solar-thermal power (CSP) technologies use mirrors to concentrate sunlight onto a receiver, which can readily reach high temperatures. When CSP is used for industrial processes, the concentrated sunlight heats a heat transfer fluid, which can be used to deliver heat for storage or provide the heat needed for industrial applications, known as industrial heat. Industrial heat refers to heat that is used to transform materials into useful products. Converting energy from sunlight directly to thermal energy reduces energy losses, making its application in industrial processes highly efficient and cost effective. In some cases, the focused sunlight can be delivered directly to the thermal process and at the required temperatures, alleviating the need for intermediary materials and processes.

Solar photovoltaic (PV) technologies, or solar panels, can be used to generate electricity for heaters used in industrial processes. Currently, most industrial heat is generated by burning fossil fuels, limiting PV application in the space, but the U.S. Department of Energy (DOE) is working to establish a new institute to drive industrial decarbonization through the electrification of process heat.

How is Solar Power Being Used for Industrial Processes?

Solar-thermal power is capable of generating heat at a wide range of temperatures, from below 400°C to over 1000°C, depending on the technology. This makes CSP well suited for a variety of industrial applications, from relatively low-temperature food-production processes to chemical processes that require high temperatures. It even has the potential to generate heat for industrial applications like enhanced oil recovery, mineral processing, cement manufacturing, and iron and steel production. Researchers are making progress on technologies that use CSP to produce solar fuels

Solar-Powered Food Production

Currently, CSP technologies are used to provide heat to the U.S. food and beverage industry, including nut processing and dairy pasteurization. Horizon Nut has worked with Sunvapor, generating heat from CSP to make steam, which is directly used to blanch, pasteurize, and roast nuts like pistachios and almonds, powering an otherwise energy-intensive process with renewable solar power. Another project worked to integrated CSP into the dairy pasteurization process at a cheese factory. Additionally, Sandia National Laboratories conducted a fun experiment where they successfully used thermal energy to roast a batch of chiles

Solar Desalination

Concentrated Solar Power is also being used for water desalination in the United States. The process of removing salt from seawater or other brackish water can be expensive, energy-intensive, and disruptive to ecosystems. But companies like Trevi Systems, Inc. are using thermal energy from CSP to heat the water, separating any additives used in the desalination process from the fresh water. Not only does it rid the water of additives used in the desalination process, but it also allows for those additives to be reused, making water desalination that much more resource efficient. It can also be used to clean water produced from oil and gas wells, concentrated brines, and some industrial and agricultural wastewaters.