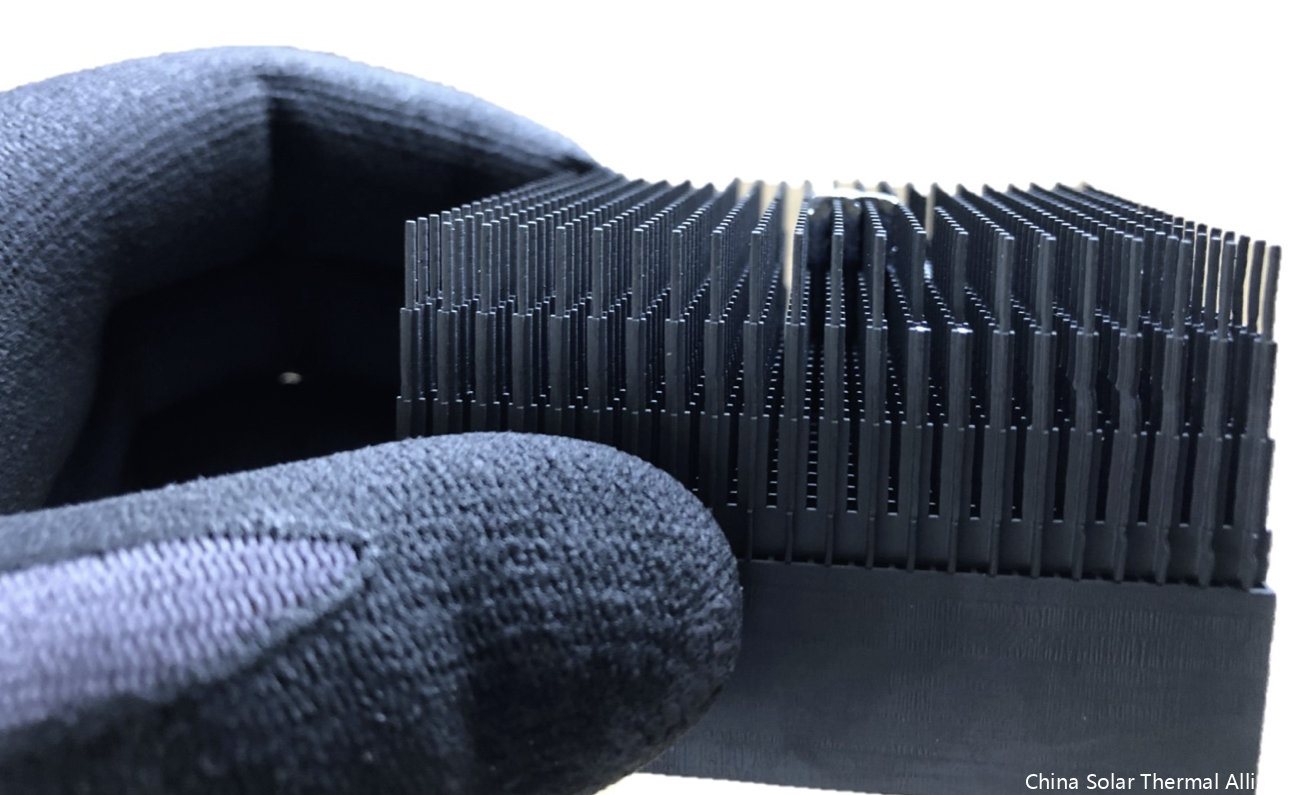

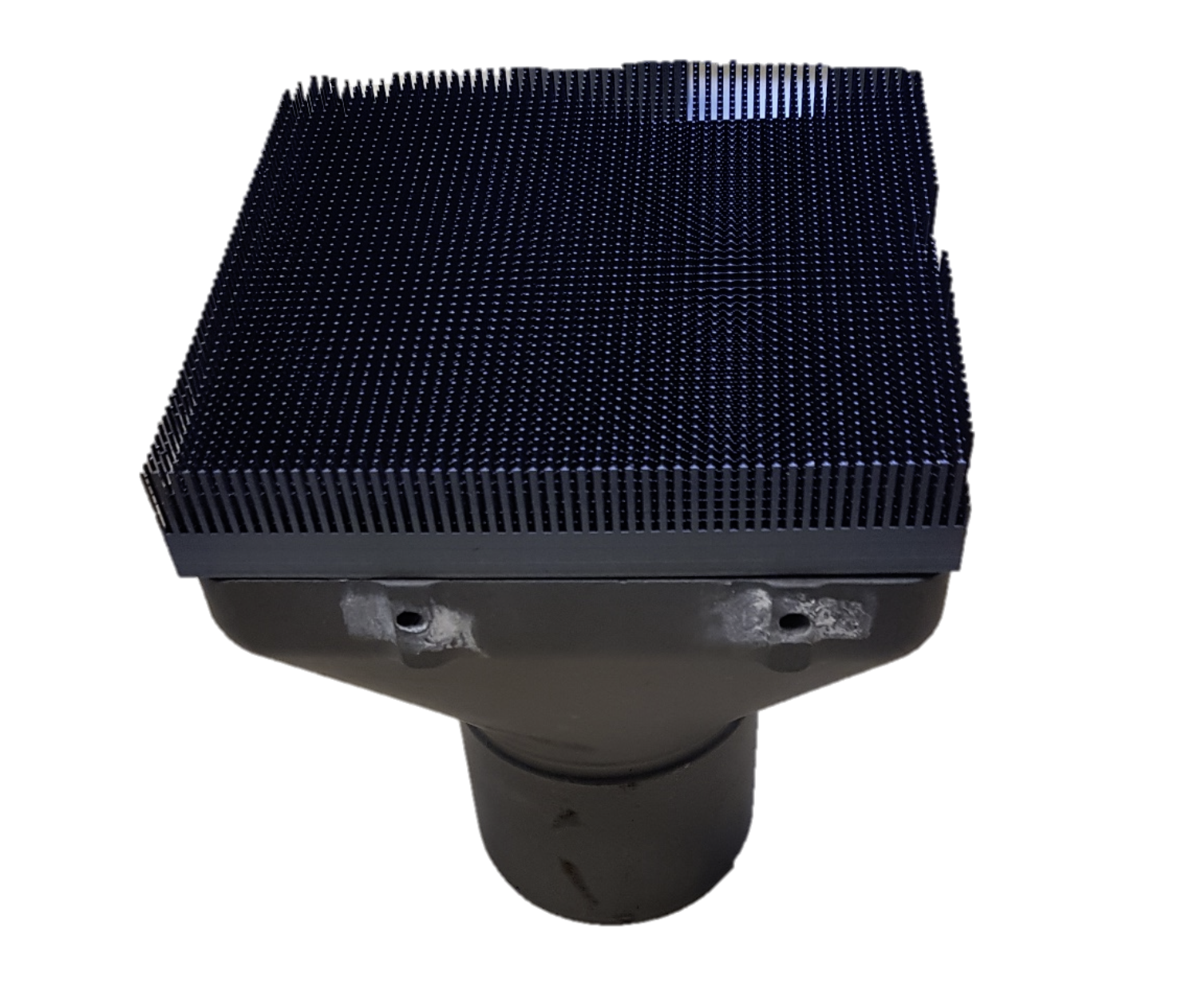

Screen-printed ceramic absorber structure made by Exentis Group.

With innovation in its core component – the volumetric absorber – the Open Volumetric Receiver (OVR) can reach 90% efficiency and beyond

Innovation:

In a recent R&D project conducted by a consortium of the German companies Kraftanlagen Energies & Services GmbH, Vitesco Emitec and Exentis Group together with the German Aerospace Centre it was shown that the efficiency potential of the volumetric receiver is far from being exhausted with the absorber structures currently available.

Extremely fine-scaled three-dimensionally structured geometries were designed according to the manufacturing capabilities of the involved companies. For the structural design a new simulation-based optimization method was applied and specialists from the manufacturing companies were involved.

Background

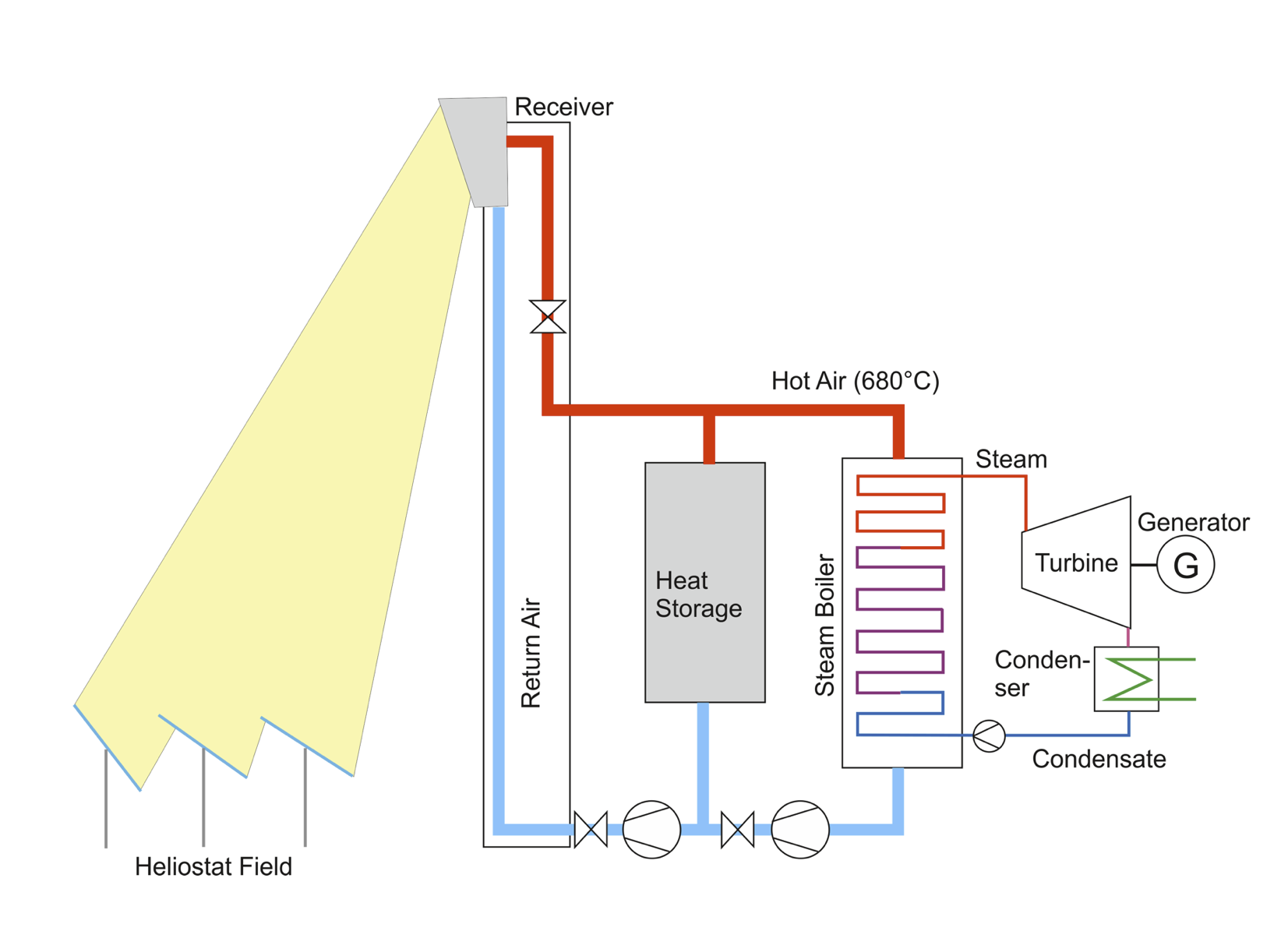

Like the currently most-deployed molten salt receiver, the open volumetric air receiver (OVR) is the only advanced receiver technology that offers a proven, effective and scalable storage concept.

FIGURE 1: Schematic of solar power plant with open volumetric receiver (OVR).

In addition, OVR technology has significant advantages in simplicity and robustness of operation compared to plants with molten salt receivers. With air exit temperatures of 650°C and beyond, it has the highest upper process temperature currently available, opening up the potential for using modern high-efficiency 620°C steam processes.

The OVR technology has been developed to a high degree of maturity over the last two decades and is being demonstrated as a complete power plant system in the German Solar Tower Jülich, an experimental power plant operated by the German Aerospace Centre (FIGURE 2).

FIGURE 2: Solar Tower Jülich experimental power plant in operation.

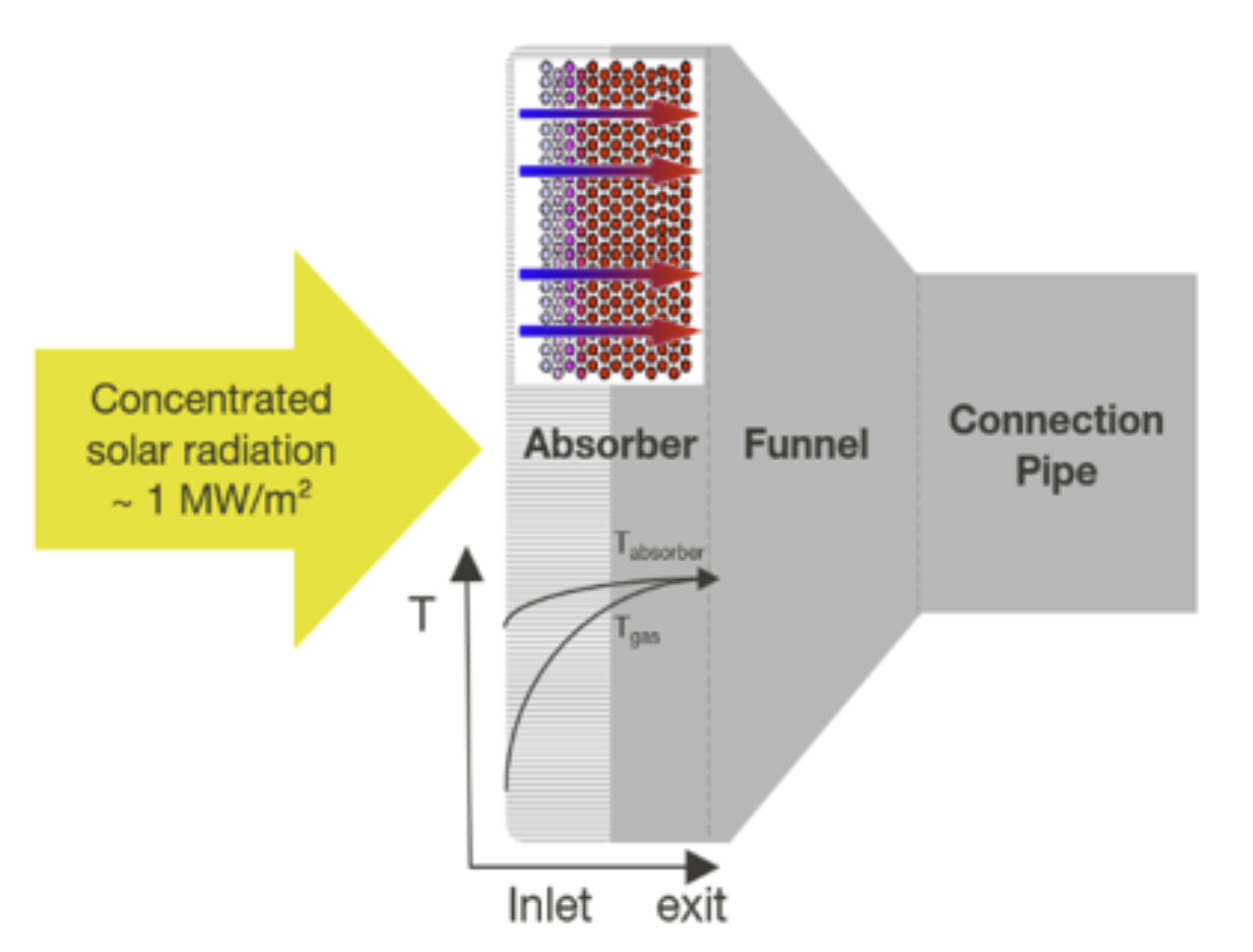

The volumetric absorber, the core component of the OVR technology, is a porous structure which allows the concentrated solar radiation to penetrate deeply into its volume to be absorbed and transferred as heat to the parallel gas flow by the large inner surface (FIGURE 3).

Typical materials used as absorbers are meshes of metal wires from temperature resistant steel alloys, reticulated foam structures made from ceramics or channel-like structures made from steel or ceramics.

FIGURE 3: Working principle of volumetric absorber.

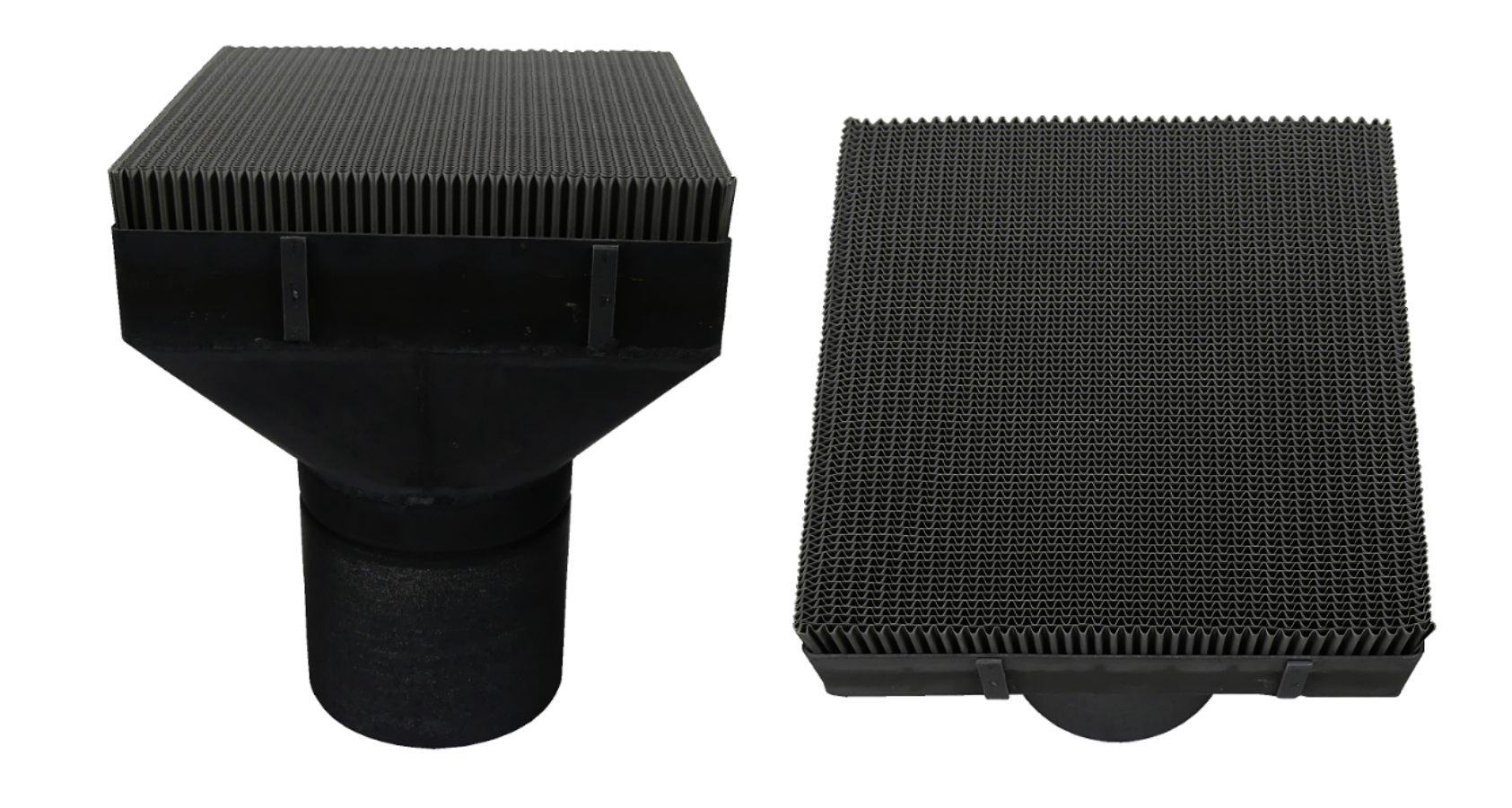

The current state of the art absorber, which is also deployed in the Solar Tower Jülich, consists of extruded honeycombs made of silicon carbide ceramics with a cellularity of about 80 cpsi and 50% open porosity (FIGURE 4).

FIGURE 4: State-of-the-art absorber module with ceramic honeycomb

The project focused on innovating two production technologies:

Vitesco Emitec produced a body of channel structures made from alternating pairs of planar and corrugated ultra-thin metal sheets (~50 micrometer) of a high-temperature steel alloy. The metal sheets can vary in length and orientation (FIGURE 5).

FIGURE 5: Vitesco Emitec’s absorber module with metal-foil channel structure.

FIGURE 6: Exentis Group’s absorber module with ceramic pin front structure.

Exentis Group produced channel structures with an innovative additive manufacturing technology: screen printing with SiC ceramics. Their honeycomb-based design is characterized by channels ending in very thin pins towards the irradiated front (FIGURE 6).

Testing

In a two-stage design process the new absorber structures were first manufactured and tested in 60mm x 60mm probe size before they were produced in module size of 140mm x 140mm compatible to the receiver on the Solar Tower Jülich.

Testing of both sizes was done in a testbed in DLR’s Synlight ® artificial solar simulator to measure the thermal efficiency in comparison to the state-of-the-art absorber. Afterwards, the new absorbers in module size were operated with concentrated solar radiation in the Solar Tower Jülich for several days to prove their stability under real environment with transients, especially due to clouds.

Results

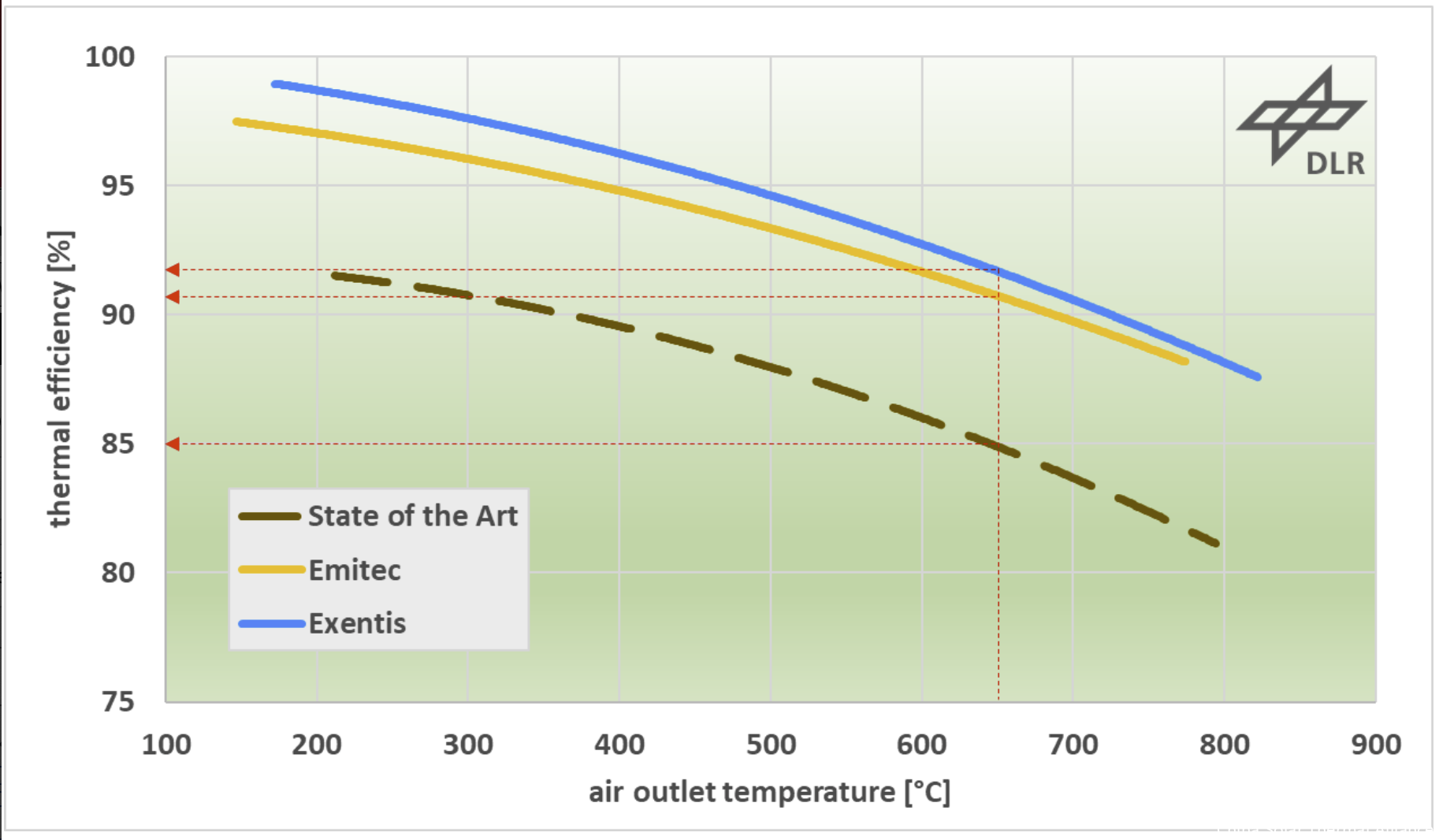

The measurement results reveal a significant advantage in thermal efficiency of the new absorber structures compared to a state-of-the-art absorber (FIGURE 7). At the reference temperature of 650°C the Vitesco Emitec structure shows 91% and the Exentis Group structure 92% thermal efficiency, which are +6 respectively +7%-points with respect to the state of the art.

The high open porosity at the irradiated front of the new absorbers allows the radiation to penetrate deep into their volume and the high inner surface area ensures effective heat transfer to the air. The pins at the front of the screen-printed absorbers from Exentis Group allow especially deep penetration independently from the direction of the incoming radiation leading to a further advantage in efficiency.

FIGURE 7: Comparison of thermal efficiency of new absorber structures with state-of-the-art absorber.

Impact

The R&D project showed that advanced absorber structures made with modern manufacturing techniques can achieve thermal efficiencies of 90% and beyond, realizing the theoretically predicted high potential of the OVR technology. With an efficiency above 90% the OVR also draws level with the currently prevailing molten salt receiver.

An efficiency improvement in the core component of the absorber has direct impact on the profitability of the total plant. 8% higher efficiency means about 8% less heliostats needed in the solar field. In a heliostat field of 600.000 m² for assumed cost of 100 €/m² this efficiency improvement results in investment savings of more than 4.5 Mio € !

Outlook

The results of the screen-printed absorber structure show the large potential of this additive manufacturing technology and give hope for high efficiency also at higher application temperatures. Nevertheless, this absorber development is still at an early stage regarding long term industrial usability in a harsh environment.

The metal-foil absorber on the other hand relies on decades of development in the automotive sector and is virtually ready for mass production and immediate use with the required service life.

Acknowledgement

This work was supported by the Federal Ministry for Economic Affairs and Climate Action on the basis of a decision by the German Bundestag.

Further Reading

Schwarzbözl, P., Giuliano, St., Noureldin, K., Doerbeck, T., Rossello, A. and Schrüfer, J. (2020) Annual Performance Assessment of a 50 MWe Commercial Solar Tower Plant with Improved Open Volumetric Receiver. In: SOLARPACES 2020: 26th International Conference on Concentrating Solar Power and Chemical Energy Systems (2445). AIP Publishing. doi: 10.1063/5.0085758.

Broeske, R. T., Schwarzbözl, P., Birkigt, L., Dung, S., Müller, B., and Doerbeck, T. (2021) Innovative 3D-Shaped Structures as Volumetric Absorbers. 27th SolarPACES Conference, 27. Sep. – 01. Okt. 2021.

Birkigt, L., Hennicke, J., Kirchner, R. (2022) 3D Screen Printing of Solar Absorbers Made of SiSiC, Sintered in an Efficient High-Performance Furnace. cfi/Ber. DKG 99 (2022) No. 2

Broeske, R. T., Schwarzbözl, P., & Hoffschmidt, B. (2022). A new partitioned 1D LTNE continuum model for the simulation of 3D-shaped honeycomb absorbers. Solar Energy, 236, 533-547. doi: 10.1016/j.solener.2022.02.024

Broeske, R. T., Schwarzbözl, P., & Hoffschmidt, B. (2022). Multi-dimensional numerical analysis of flow instabilities in 3D-shaped honeycomb absorbers. Solar Energy, 247, 86-95. doi: 10.1016/j.solener.2022.10.007.