Global solar energy supplies are growing rapidly, with nearly 10 times as much solar capacity installed today as there was a decade ago. Leading the boom is the photovoltaic (PV) panel, which converts sunlight into electricity using semiconductors. But even as the glossy rectangles become increasingly cheaper and ubiquitous, solar PV alone can’t solve the nagging question: What to do when the sun isn’t shining? As electric utilities and policymakers seek solutions for storing and dispatching energy on demand, concentrating solar-thermal power (CSP) is once again gaining traction.

Heliostats are seen during the inauguration of the Cerro Dominador thermal solar power plant, in Maria Elena, Chile June 8, 2021. REUTERS/Ivan Alvarado – RC2IWN9BCZC8

Solar-thermal systems use sun-tracking mirrors to reflect sunlight onto a receiver, which contains a high-temperature fluid that stores heat. The heat can drive steam turbines or engines to generate electricity around the clock. Or, solar thermal can directly provide heat for industrial processes to make steel, cement, and chemicals—all energy-intensive sectors that are difficult to clean up. With U.S. states and countries adopting measures to curb greenhouse gas emissions, now «might be the right time for CSP to become more broadly applicable,» said Margaret Gordon, the CSP program manager at Sandia National Laboratories in Albuquerque, N.M.

The first utility-scale solar-thermal plants were built in the 1980s. Today, nearly 120 projects operate worldwide, and Spain claims more than a third of total installed capacity. In recent years, however, CSP development stalled amid the rapidly falling cost of solar PV. Massive solar-thermal arrays require steep upfront investment. Unlike solar PV, the mirrors, heat exchangers, and other key components aren’t yet «off-the-shelf» ready, which adds time and expense to project development, Gordon said. Even so, solar-thermal developments continue to unfurl across the planet’s sunniest expanses, driven by the growing demand for energy storage and cleaner heat sources. IEEE Spectrum looked at four new solar-thermal projects—each representing a different CSP technology—that are curbing emissions by harnessing the sun’s heat.

Power Tower

Cerro Dominador

Cerro Dominator: 100-MW solar-thermal power tower + 100-MW solar PV plant.

Atacama Desert, Chile

The US $1.4 billion project began full operations in June. The 700-hectare complex has 10,600 mirrors (or «heliostats») that direct sunlight to a 252-meter-tall tower. Inside the tower, molten salts are heated to 565 °C and flow down into storage tanks, turning water into steam to drive turbines. The closed-loop system has a record 17.5-hour thermal storage capacity, allowing operators to provide electricity 24/7.

"It’s flexible. It’s like a big battery of molten salt instead of lithium," said Fernando Gonzalez, CEO of Cerro Dominador.

Bottom line: Among CSP, molten-salt power towers have the greatest cost-reduction potential, thanks to higher operating temperatures and improved efficiencies, according to the International Renewable Energy Agency (IRENA).

Parabolic Dish Concentrator

Solarflux

Solarflux Focus: 10-kW prototype dish.

Pennsylvania, United States

Solarflux’s prototype unit is a simplified, lower-cost version of a decades-old concept, operating at Pennsylvania State University’s campus in Berks County. Polished aluminum petals cover a 14-square-meter aperture, beaming sunlight onto a receiver at the focal point. The Focus dish is mounted on a dual-axis tracking system, so it’s always facing the sun. The receiver transfers heat to an engine or generator and, depending on the heat transfer fluid, can deliver thermal energy of up to 600 °C, the company claims. A 30-kilowatt, 42-square-meter aperture production unit is in development.

Bottom line: Focus may be best suited for «distributed thermal» applications, with one or dozens of dishes directly providing heat to factories, wastewater treatment plants, or desalination facilities, said Naoise Irwin, CEO of Solarflux.

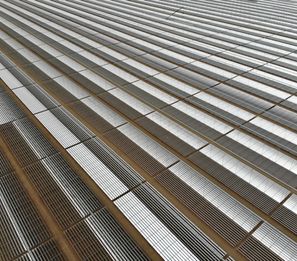

Linear Fresnel

Zhang Xiaoliang/VCG/Getty Images

Lanzhou Dunhuang Dacheng: 50-MW Fresnel project.

Dunhuang, China

Built in an industrial park in Northwest China, this project began commercial operations in June 2020. Flat reflective panels are arranged like the stepped lenses of a lighthouse lamp (which typically also uses a Fresnel lens), concentrating sunlight on a loop of overhead pipes. Panels are oriented north-south to track the sun. In a first for commercial Fresnel projects, this installation uses molten salts—not thermal oil—in the pipes. The fluid heats to above 535 °C and flows to a steam turbine or into two molten-salt storage tanks, with a total thermal storage capacity of 15 hours.

Bottom line: Linear Fresnel hasn’t yet scaled to the level of towers or troughs, partly due to lower power-cycle efficiencies and higher electricity production costs, says Ken Armijo, a mechanical engineer at Sandia, which previously operated a molten-salt Fresnel test loop facility in Albuquerque.

Parabolic Trough

ACWA Power

Noor Energy 1: 600-MW total parabolic trough system + 100-MW power tower + 250-MW solar PV plant.

Dubai, United Arab Emirates

The massive US $4.4 billion complex includes three 200-MW parabolic trough arrays, the first of which will begin commissioning this year. Each unit includes 2,120 mirrored modules, which concentrate the sun’s energy onto an absorber tube placed at each module’s focal point. A low-viscosity oil in the absorber tubes rises to 393 °C, then flows into the power block. From there, the heat-transfer fluid is used to drive steam turbines, or it’s sent to molten-salt thermal energy storage tanks—each with a 12-hour thermal storage capacity. When completed in late 2022, Noor Energy 1 will be the world’s largest CSP project.

Bottom line: Parabolic trough systems are considered the most mature and (for now) lowest-cost CSP technology. In 2020, troughs made up two-thirds of the global installed CSP capacity.

is an IEEE Spectrum contributing editor based in New York City. She has worked as a staff writer for publications in New York and Mexico City, covering a wide range of energy and environment issues in the United States and Latin America.