Cutting-edge camera technology and irradiation forecasts could increase CSP revenues by several percentage points and boost competitiveness in key China and Middle East markets, researchers say.

European CSP researchers are combining real-time sky imaging with irradiance forecasting to increase revenues and component lifespans. (Image credit: DLR)

In November, U.S. technology developer Heliogen hit CSP tower temperatures of over 1,000° C by using cameras and advanced computer vision software to align heliostats more accurately.

In Europe, tests of WobaS All Sky Imager (ASI) technology at the 50 MW La Africana parabolic trough plant in Spain increased plant revenue by 2% over a two year period.

Developed by Germany's DLR Institute of Solar Research (DLR), CSP Services GmbH and TSK Flagsol Engineering GmbH, the WobaS ASI tracks irradiance variability, typically caused by cloud movement, and predicts energy availability over the next 15 minutes.

In a further step, the WobaS teams are now integrating the camera technology with irradiation forecasting to demonstrate predictive operating gains.

Funded by the German government, the ‘WobaS-A’ project will show the ASI can help forecast irradiation over a 15 minute window.

Greater revenues are expected when the forecast DNI maps are integrated, Stefan Wilbert, Head of the Solar Energy Meteorology Group at DLR, told New Energy Update.

The 2% efficiency increase at La Africana was achieved “using only the direct normal irradiance (DNI) maps for the time of the image acquisition," he noted.

The combination of short-term weather forecasting and smart technology could significantly boost CSP revenues. "Nowcasting" of DNI predictions for the 15 minutes ahead could increase CSP efficiency by 8% for CSP tower plants and 4% for parabolic trough plants, European researchers said in the 2018 paper, ‘Impact of DNI nowcasting on annual revenues of CSP plants.’

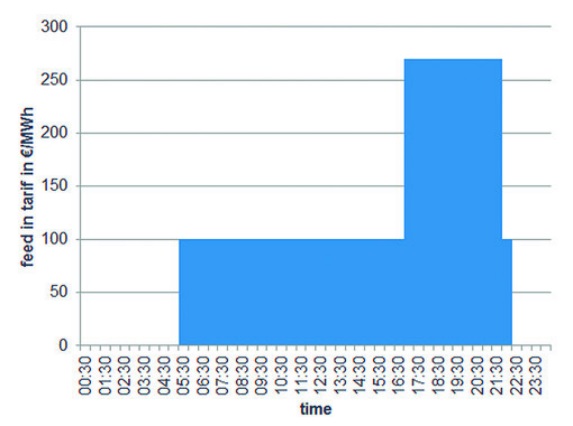

Based on a 110 MW plant with peak tariff pricing, this implies additional revenues of "450,000 euros to 2.9 million euros [$503,000- $3.2 million] per year when adding a nowcasting scheme to the solar production forecast tool already in operation at some power plants," the research team, which included DLR, said.

Time of delivery tariff used in DNI nowcasting study

Source: 'Impact of DNI nowcasting on annual revenues of CSP plants' (J. Dersch et al.)

The separate EU-funded DNICast research project has already demonstrated several nowcast hardware and application advancements for CSP plants, using ground observations, meteorological satellites and numerical weather prediction (NWP).

Completed in 2017, the DNICast research showed the integration of these methods offers more reliable DNI estimates and provides a blueprint for how to merge and adapt these different applications according to plant characteristics and offtaker needs.

Cloud cover

The WobaS system uses four 180-degree fisheye lens cameras that measure cloud location, height, shape, direction of movement and speed.

The data is transposed onto plant DNI measurements to determine expected available energy over the next 15 minutes.

Nowcasting-- defined as forecast windows of one to 45 minutes-- allows CSP operators to adjust thermodynamic cycles in response to variable cloud conditions to maintain desired temperature levels. This can help operators mitigate sudden swings in solar supply and protect equipment, without defocusing or refocusing reflectors.

"ASI integration in a parabolic trough system allows us, for instance, to regulate the flow of heat transfer medium in the power plant so that all collectors remain focused even with fluctuating solar radiation,” Tobias Hirsch, project manager at DLR said in a statement.

The technology could be particularly useful in China and the Middle East and North Africa (MENA), two key CSP growth regions, where dust storms and air pollution can cause significant DNI variability.

While the potential gains will depend on DNI variability at the site, developers expect "significant benefits for all typical CSP sites," Wilbert said.

Even at sites with no sky obstructions, the new control method increased plant efficiency by around 1%, as a favorable forecast allowed the plant to be operated less conservatively and more efficiently, he said.

New controls

Other ASI technologies include SteadyEye, developed by France’s Steadysun and Sky Cam Vision, developed by Germany's Reuniwatt.

A key challenge for commercial deployment of these systems is the compatibility with existing plant control systems.

For the WoBaS system, operators will need to adapt plant control algorithms to take into account the spatial and temporal variability of the DNI maps derived from the ASI.

Controllers currently in use are not designed to apply the ASI data efficiently, Wilbert said.

The WoBaS team has developed an adapted controller in a simulation environment and will soon demonstrate it at a 50 MW parabolic trough plant, he said.

Balancing revenues

The growing penetration of PV and wind technology is increasing the value of dispatchable power generation.

CSP with storage allows operators to dispatch power during times of peak demand or low PV or wind output, accessing higher market prices.

Nowcasting can help operators decide between dispatching immediately or storing until higher revenues can be achieved.

Such technologies will also help generators and grid operators balance the grid more efficiently.

“Together with satellite or numerical weather model-based forecasts, All Sky Imagers can help to dispatch the electricity in the optimal way which contributes to a stable electricity grid,” Wilbert said.

Protecting parts

The WobaS system could yield additional gains when combined with extended forecasting systems, such as the FoSyS system developed by TSK Flagsol and DLR which forecasts DNI up to 14-days ahead.

On top of higher revenues, the ASI forecasts can help to reduce temperature gradients in plant components caused by sudden radiation changes. Longer forecasting windows would allow operators to make more predictive operating and maintenance (O&M) decisions to improve performance, reduce costs and limit component degradation.

“Besides higher plant efficiencies, we also expect increased component lifetimes,” Wilbert said.