CSP needs high solar irradiation, which is often found in the desert areas, where the land is rarely used for other purposes. To evaluate how CSP technology could withstand different weather conditions there is no better place than Northwestern region of China. This region has it all: high speed wind, dust, extreme temperatures, and lack of water supply. Since 2016, ten commercial CSP power plant was built in the Northwestern region of China.

We decided to talk with Cosin Solar’s chief engineer to understand how he deals with these challenges and how it affects the current power plant operation. Let’s talk about each weather condition separately, taking an example the COSIN SOLAR’s 10 and 50 MW Delingha projects data:

1) The Northwestern region of China is famous for its high-speed wind, which could damage heliostats. Was it the case for Delingha power plants?

– “Usually, equipment design is adjusted according to the different wind speeds in the specific location. In Delingha, the heliostat working wind speed is 18m/s (corresponding to 10m high instantaneous wind speed), but the heliostat can easily withstand even higher wind speed. Here are the local wind speed data:

The heliostat field of China’s first 10 MW tower CSP has 21500 heliostats and only 10 heliostats were damaged over 7 years of operation period. This real time data shows that if well designed, wind has a very low impact to the overall lifespan of heliostats and therefore to the overall performance of the plant.”

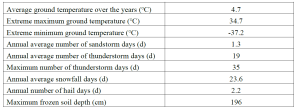

2) Usually CSP plants are built in very hot places, but in case of Delingha the power plant should resist not only hot, but also extremely cold temperature, did you have any challenges with these temperature differences?

– Indeed, here the winter is very cold, with a minimum of -34.7 ℃ and a maximum of 37 ℃ in summer.

However, we already knew about these challenges during the design stage. In 2013 we built a 10 MW power plant and only after we resolved all the small issues appearing on the smaller plant, we challenged ourselves to build 50 MW commercial power plant, commissioned in 2018. Throughout 10 years of operating experience on CSP power plants, we have learned very well how to design and operate a power plant in these extreme weather conditions.

3) Desert areas usually suffer from lack of water, how this affected the power plant design and operation?

“To save water, Chinese engineers usually choose the dry-cooling system for CSP plants instead of wet cooling. Also, we developed an automatic heliostat cleaning vehicle, which can effectively clean the heliostats even at night, reducing water consumption, and lowering the impact of cleaning to the power generation during the day. We even got the SolarPACES

Technology Innovation Award in 2020 for this cleaning vehicle.

Interesting fact that we noticed for Delingha location, – after cleaning heliostats, water drops are falling on the ground, contributing to the grass grow. Here the pictures with the land before installing the power plant and after. After the construction, the heliostats reflect sunlight, shield the plants under the mirror field from the excessive sun’s burning, while reducing the ground temperature and water evaporation.”

The original land of a power station site (July, 2015):

Landform after the construction of the tower CSP station (july, 2021):

4) The Gobi Desert is also one of the world’s most abundant sources of dust and sand, how this affects the power plant generation?

– “The reflectivity at the design point of the tower heliostat is 94%. In actual operation, because of the dust, the actual reflectance is lower and depends on the cleanliness of heliostats. We need to balance the cost of cleaning the heliostats versus the power we will gain by increasing the reflectance of heliostats. As we knew already about the average frequency of sandstorm in the region, we considered this factor in the design of the power plant, which lowered the risks for power plant power production. Actually because of increased vegetation around the solar field, the amount of dust on heliostats is also reduced over time.”

“The Delingha project is located at the attitude of 2900 meters above the sea level, meaning that less oxygen is available for breathing at such higher attitudes and it is much more difficult to work there. I think if CSP power plant works so well in Delingha region with such a harsh weather condition, it could work anywhere. The most important is to know about these challenges and prepare the design of the power plant well ahead. The technology is already developed enough to overcome these barriers.” – concluded Jianxiang Jin.

For Parabolic Trough technology, “Shams1” in Abu Dabi is a great example of the power plant, which also withstands a very harsh desert conditions, and well operate since 2010. Similar problems with high-speed wind, sandstorm and extreme temperatures were well managed and proved that the CSP industry knows how to manage its challenges (for more info: Shams 1 – Design and operational experiences of the 100MW – 540°C CSP plant in Abu Dhabi (scitation.org) ).

Interview with Cosin Solar chief engineer –Jianxiang Jin

Interview recorded and edited by Alina Gilmanova and Haobin Zhang. Special thanks for Jianxiang Jin for the interview. cspfocus.cn